Other Parts Discussed in Thread: SN74LVCC4245A-EP,

Dear Engineers,

In ours control system we're trying to approve according to the standard EN 50124-1 (Railway applications - Insulation coordination).

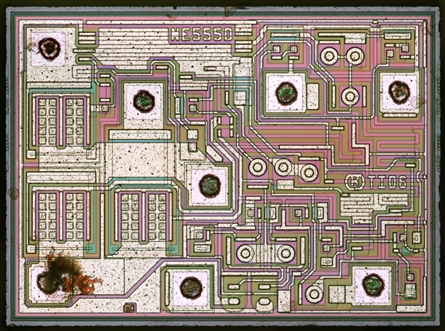

Minimum creepage distances (based on rated insulation voltage up to 50V) between channels is 0,025mm inside component.

What are the minimum distances between channels in the inside components SN74ALVC164245 and SN74LVCC4245A-EP?

Thanks,

Michal Matějka