Other Parts Discussed in Thread: HALCOGEN

Hi,

I am trying to do analog loop back tests for N2HET.

What I am trying to do is:

1. Generated a PWM on HET[12]

2. Connected HET[12] and HET[13] in analog loop back mode

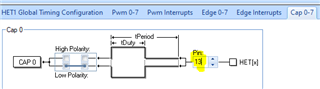

3. Configured CAP0 to measure the PWM signal on HET[13]

4. Measured the PWM dutycycle and period using the function capGetSignal

But I am unable to get the captured signals pwm and dutycycle. Is there any thing I am doing wrong ?

A code snippet of what I am trying to do is posted:

void test_analog_n2het()

{

/* configure LBPDIR[12/13] = 1, HR structure 12 will be output and

* HR structure 13 will be input*/

/* configure LBPTSTENA[16-19] = 0xAh to enable loop back test*/

hetREG1->LBPDIR |= 0x000A0040U;

/* configure LBPSEL[12/13] = 1, HR structures 12 & 13 will be internally connected in loop

back mode.*/

/* configure LBPTYPE[12/13] = 1. This will configure HR structure 12 - 13 in analogue

* loop back mode */

hetREG1->LBPSEL |= 0x00400040U;

}

void measure_cap_signal()

{

capGetSignal(hetRAM1, 0U, &het_signal_capture);

printf("The PWM of captured signal : %f\n", het_signal_capture.period);

}

I have noted the PWM generation on HET[12] is fine.

Can any one please tell me what is going wrong ?

Regard

S