Hi team,

I have a question for the customer.

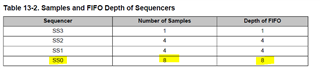

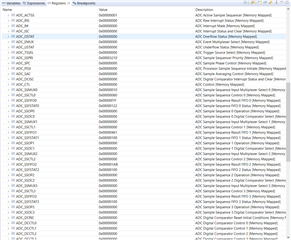

I have a problem with adc device TM4C123 I DESIGN DRIVE TO WORK BU POLLING TO CONTROL THE LED SWITCH ON /OFF BY THE VALUE of FIFO REGISTER, although I flow the instruction section in the datasheet the code did not work properly and the led did not turn off in the if condition becomes true. I try to debug the code and I found that everything works fine so I pass this code to e2e team to discover this problem.

Thank you very much for your help.

Best regards,