Part Number: TMS570LC4357

Other Parts Discussed in Thread: HALCOGEN

Hello Team,

I was trying to fetch the encoder signals of the motor in my project.

These are the statements I have written for reading the master motor encoder signals :-

capGetSignal(hetRAM2, cap0, &enc_a_master);//enc_b_master /* CAP0 = N2HET2_19 */ /* Working */

capGetSignal(hetRAM2, cap1, &enc_b_master);//enc_a_master /* CAP1 = N2HET2_20 */ /* Not working */

Here the first statement is working properly, but N2HET2_20 is not working.

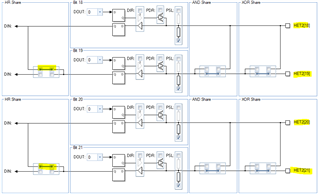

Please refer the below attached screenshot of halcogen configurations for HET2:

Kindly let me know if the configurations are correct or is there any thing missing.