Hi team,

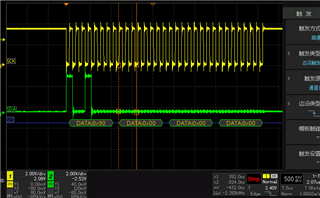

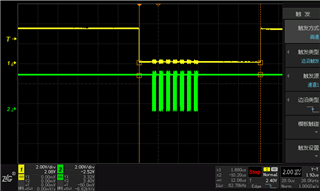

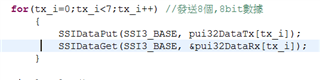

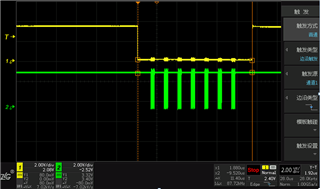

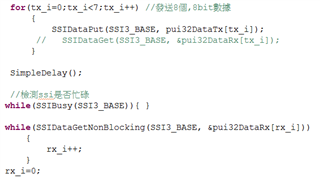

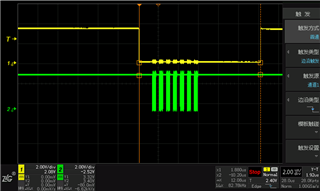

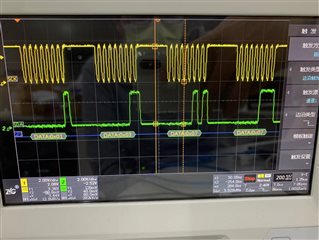

Using this M4 for SPI use, using oscilloscope for frequency and TX measurement, it is found that the waveform cannot be "square wave".

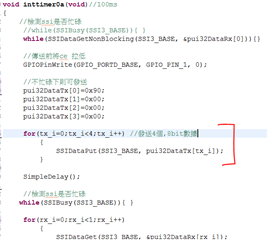

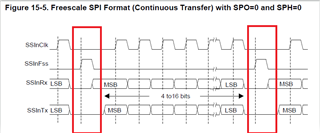

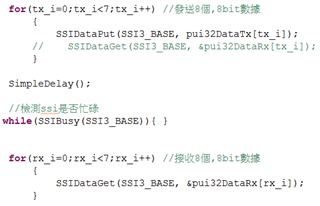

Causes the data resolution to be abnormal and the configuration is as follows:

Frequency: 80Mhz SPI: 20Mhz

The waveform is the same on the board made by customer as the TivaTm TM4C123G development board test (no load measurement on the circuit SPI pin).

The waveform data is basically matched to the program transmit and the frequency measurement is 20Mhz. Only the frequency cannot be square. As this 20Mhz is decreasing, the waveform will gradually become square

So the customer would like to know is there a maximum output frequency for this IC? ? Or does it need to work with an external circuit?

Could you help check this case? Thanks.

Best Regards,

Cherry