Other Parts Discussed in Thread: TMDXRM46HDK

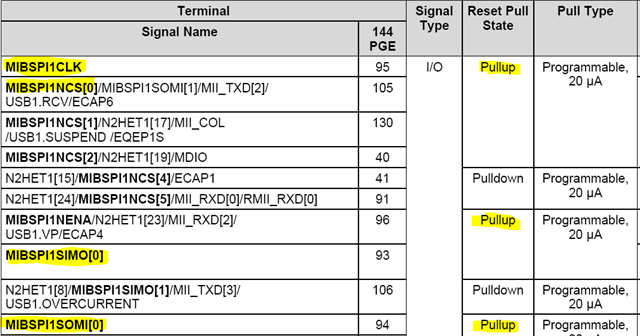

Hello, my name is Francisco, engineer of the R+D+i Department of the Rother Industries & Technology company. I would want to use a MicroSDXC of 64 or 128 GB, but it would communicate with the RM46L852 microcontroller via SPI protocol. Therefore, I have contacted Sandisk about a microSDXC that meets this requirement, they told me that the most suitable card for this application is the Micro SDXC High Endurance, but they recommended me that I should contact Texas Instrument about this issue. So I would like to know your opinion about it and what Micro SDXC I could use for an application where the host (RM46L852) will be writing data on the cards continuously (every 10 ms).

According to Physical Layer Simplified Specification of SD Association, the feature of SPI communication is mandatory for SDXC cards. An example of this aplication is the TMDXRM46HDK Development kit.

Please, explain the reasons for your answers. I would appreciate the answer from an expert who has studied the Physical Layer Specification.

Best regards,

Francisco.