Other Parts Discussed in Thread: TMS320F2812

Hi.. Experts,

Recently I had purchased XDS200 USB Emulator (INV 5930563619 Dt- 27 May 2023) from TI Web site.

I received the material on 16/06/2023 through DHL courier. The serial no. of product is TC57500.

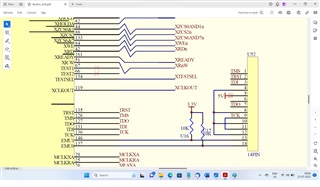

I started using it from the next day. We have custom CPU board for our CNC Controller based on TMS320F2812 processor.

We were using Spectrum Digital JTAG for our custom board from 2015.

Till 26/6/2023 we were using it for debugging & programming.

In between, some time I had Error 1156 of low power mode but after power on reset to board & JTAG , it was working properly.

On 27/06/2023 morning it stopped working by showing Error 183 - cable break error far from itself.

I contacted TI customer support as it was under warranty to understand problem & solution.

TI customer support confirm that it is cable break issue with description & possible check point.

Being a cable break issue, I opened JTAG box to check continuity of FRC cable, when I saw a PCB component U7 is burnt down.

I have attached picture of PCB.

I am not sure why U7 burnt as particular CPU board design is properly tested & working since 2006 & we have been using Spectrum Digital, Blackhawk JTAG with this particular design for last 15 years and particular JTAG was also working from 16th to 26th June.

TI Customer care earlier confirmed that it is warranty issue & suggested me to post query on TIE2E platform to understand possible cause.

In between as this process was taking time, I purchased same Blackhawk JTAG(XDS200 USB Emulator ) from Mouser electronics as it was out of stock on TI web site and started working with it. It is working fine.

Can experts from the TI E2E forum please let us know possible cause? OR it is manufacturing issue.

Thanks & regards

Abhijit Kelkar