Other Parts Discussed in Thread: TM4C123GH6PM

Hi Team

I am trying to read iternal ADC in tm4c1294x EVK channel by giving 3.3 internal voltage

this is my code to read PE2 GPIO channel1

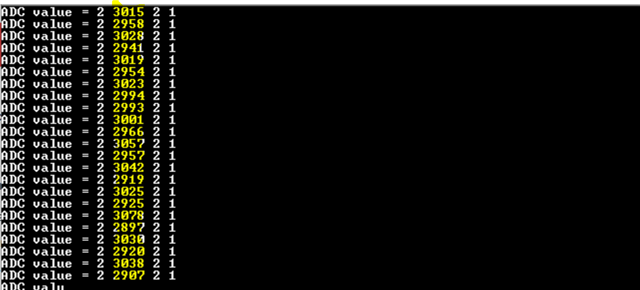

I could read only 2900-3000 as raw value could not get exactly 3300

PFA of the source code can you please review it and can tell any changes to be mad

/*

* Adc.c

*

* Created on: Aug 30, 2023

* Author: balasubramanian_sund

*/

//*****************************************************************************

//

// temperature_sensor.c - Example demonstrating the internal ADC temperature

// sensor.

//

// Copyright (c) 2010-2014 Texas Instruments Incorporated. All rights reserved.

// Software License Agreement

//

// Redistribution and use in source and binary forms, with or without

// modification, are permitted provided that the following conditions

// are met:

//

// Redistributions of source code must retain the above copyright

// notice, this list of conditions and the following disclaimer.

//

// Redistributions in binary form must reproduce the above copyright

// notice, this list of conditions and the following disclaimer in the

// documentation and/or other materials provided with the

// distribution.

//

// Neither the name of Texas Instruments Incorporated nor the names of

// its contributors may be used to endorse or promote products derived

// from this software without specific prior written permission.

//

// THIS SOFTWARE IS PROVIDED BY THE COPYRIGHT HOLDERS AND CONTRIBUTORS

// "AS IS" AND ANY EXPRESS OR IMPLIED WARRANTIES, INCLUDING, BUT NOT

// LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

// A PARTICULAR PURPOSE ARE DISCLAIMED. IN NO EVENT SHALL THE COPYRIGHT

// OWNER OR CONTRIBUTORS BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL,

// SPECIAL, EXEMPLARY, OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT

// LIMITED TO, PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES; LOSS OF USE,

// DATA, OR PROFITS; OR BUSINESS INTERRUPTION) HOWEVER CAUSED AND ON ANY

// THEORY OF LIABILITY, WHETHER IN CONTRACT, STRICT LIABILITY, OR TORT

// (INCLUDING NEGLIGENCE OR OTHERWISE) ARISING IN ANY WAY OUT OF THE USE

// OF THIS SOFTWARE, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.

//

// This is part of revision 2.1.0.12573 of the Tiva Firmware Development Package.

//

//*****************************************************************************

/*

* This code was made to show a simple ADC read.

*

* It was made from the example provided by TivaWare but it was a some modifications

* like the math

*

*

* Luís Afonso

*

*

*/

//#define PART_TM4C123GH6PM

#include <stdint.h>

#include <stdbool.h>

#include "stdlib.h"

#include "inc/hw_ints.h"

#include "inc/hw_memmap.h"

#include "inc/hw_uart.h"

#include "inc/hw_gpio.h"

#include "inc/hw_pwm.h"

#include "inc/hw_types.h"

#include "driverlib/adc.h"

#include "driverlib/timer.h"

#include "driverlib/gpio.h"

#include "driverlib/interrupt.h"

#include "driverlib/pin_map.h"

#include "driverlib/rom.h"

#include "driverlib/rom_map.h"

#include "driverlib/sysctl.h"

#include "driverlib/uart.h"

#include "driverlib/udma.h"

#include "driverlib/pwm.h"

#include "driverlib/ssi.h"

#include "driverlib/systick.h"

#include "driverlib/adc.h"

#include "utils/uartstdio.h"

#include <string.h>

#include "Adc.h"

volatile uint32_t millis=0;

void SycTickInt(){

millis++;

}

void SysTickbegin(){

SysTickPeriodSet(80000);

SysTickIntRegister(SycTickInt);

SysTickIntEnable();

SysTickEnable();

}

void Wait(uint32_t time){

uint32_t temp = millis;

while( (millis-temp) < time){

}

}

//*****************************************************************************

//

// This function sets up UART0 to be used for a console to display information

// as the example is running.

//

//*****************************************************************************

void

InitConso(void)

{

//

// Enable GPIO port A which is used for UART0 pins.

// TODO: change this to whichever GPIO port you are using.

//

SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOA);

//

// Configure the pin muxing for UART0 functions on port A0 and A1.

// This step is not necessary if your part does not support pin muxing.

// TODO: change this to select the port/pin you are using.

//

GPIOPinConfigure(GPIO_PA0_U0RX);

GPIOPinConfigure(GPIO_PA1_U0TX);

//

// Enable UART0 so that we can configure the clock.

//

SysCtlPeripheralEnable(SYSCTL_PERIPH_UART0);

//

// Use the internal 16MHz oscillator as the UART clock source.

//

UARTClockSourceSet(UART0_BASE, UART_CLOCK_PIOSC);

//

// Select the alternate (UART) function for these pins.

// TODO: change this to select the port/pin you are using.

//

GPIOPinTypeUART(GPIO_PORTA_BASE, GPIO_PIN_0 | GPIO_PIN_1);

//

// Initialize the UART for console I/O.

//

UARTStdioConfig(0, 115200, 16000000);

}

int Adc(){

SysCtlClockSet(SYSCTL_SYSDIV_2_5|SYSCTL_USE_PLL|SYSCTL_OSC_MAIN|SYSCTL_XTAL_16MHZ);

/* uint32_t g_ui32SysClock =0;

g_ui32SysClock = MAP_SysCtlClockFreqSet((SYSCTL_XTAL_25MHZ |

SYSCTL_OSC_MAIN |

SYSCTL_USE_PLL |

SYSCTL_CFG_VCO_240), 120000000);*/

SysTickbegin();

InitConso();

//

// This array is used for storing the data read from the ADC FIFO. It

// must be as large as the FIFO for the sequencer in use. This example

// uses sequence 3 which has a FIFO depth of 1. If another sequence

// was used with a deeper FIFO, then the array size must be changed.

//

uint32_t ADCValues[1]={0};

// uint32_t ADCValues[0]={0};

//

// These variables are used to store the temperature conversions for

// Celsius and Fahrenheit.

//

uint32_t TempValueC = 0;

// uint32_t TempValueF;

uint32_t ui32Count =0;

//

// Display the setup on the console.

//

UARTprintf("ADC ->\n");

UARTprintf(" Type: Internal Temperature Sensor\n");

UARTprintf(" Samples: One\n");

UARTprintf(" Update Rate: 250ms\n");

UARTprintf(" Input Pin: Internal temperature sensor\n\n");

//

// The ADC0 peripheral must be enabled for use.

//

SysCtlPeripheralEnable(SYSCTL_PERIPH_ADC0);

//ADCClockConfigSet(ADC0_BASE, ADC_CLOCK_SRC_PIOSC | ADC_CLOCK_RATE_HALF, 1);

SysCtlDelay(3);

SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOE);

GPIOPinTypeADC(GPIO_PORTE_BASE,GPIO_PIN_2);

//

// Enable sample sequence 3 with a processor signal trigger. Sequence 3

// will do a single sample when the processor sends a singal to start the

// conversion. Each ADC module has 4 programmable sequences, sequence 0

// to sequence 3. This example is arbitrarily using sequence 3.

//

ADCSequenceDisable(ADC0_BASE, 3);

ADCSequenceConfigure(ADC0_BASE, 3, ADC_TRIGGER_PROCESSOR, 0);

ADCReferenceSet(ADC0_BASE, ADC_REF_INT);

//

// Configure step 0 on sequence 3. Sample the temperature sensor

// (ADC_CTL_TS) and configure the interrupt flag (ADC_CTL_IE) to be set

// when the sample is done. Tell the ADC logic that this is the last

// conversion on sequence 3 (ADC_CTL_END). Sequence 3 has only one

// programmable step. Sequence 1 and 2 have 4 steps, and sequence 0 has

// 8 programmable steps. Since we are only doing a single conversion using

// sequence 3 we will only configure step 0. For more information on the

// ADC sequences and steps, reference the datasheet.

//

ADCSequenceStepConfigure(ADC0_BASE, 3, 0, ADC_CTL_CH1 | ADC_CTL_IE |

ADC_CTL_END);

//ADCHardwareOversampleConfigure(ADC0_BASE,64);

//

// Since sample sequence 3 is now configured, it must be enabled.

//

ADCSequenceEnable(ADC0_BASE, 3);

//

// Clear the interrupt status flag. This is done to make sure the

// interrupt flag is cleared before we sample.

//

ADCIntClear(ADC0_BASE, 3);

//

// Sample the temperature sensor forever. Display the value on the

// console.

//

while(1)

{

//

// Trigger the ADC conversion.

//

ADCProcessorTrigger(ADC0_BASE, 3);

//

// Wait for conversion to be completed.

//

while(!ADCIntStatus(ADC0_BASE, 3, false))

{

}

SysCtlDelay(3);

//

// Clear the ADC interrupt flag.

//

ADCIntClear(ADC0_BASE, 3);

//

// Read ADC Value.

//

ui32Count = ADCSequenceDataGet(ADC0_BASE, 3, ADCValues);

//

// Use non-calibrated conversion provided in the data sheet. I use floats in intermediate

// math but you could use intergers with multiplied by powers of 10 and divide on the end

// Make sure you divide last to avoid dropout.

//

// TempValueC = (uint32_t)(147.5 - ((75.0*3.3 *(float)ADCValues[0])) / 4096.0);

TempValueC = ((ADCValues[0] * 3.3) / 4095 );

//

// Get Fahrenheit value. Make sure you divide last to avoid dropout.

//

// TempValueF = ((TempValueC * 9) + 160) / 5;

//

// Display the temperature value on the console.

//

UARTprintf("ADC value = %d %4d %d %d\r\n", TempValueC, ADCValues[0] ,ADCValues[1], ui32Count);

//

// This function provides a means of generating a constant length

// delay. The function delay (in cycles) = 3 * parameter. Delay

// 250ms arbitrarily.

//

SysCtlDelay(16000000 / 12);

ADCValues[0]=0;

ADCValues[1] =0;

TempValueC = 0;

}

}

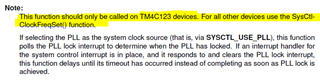

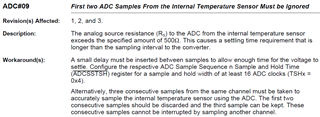

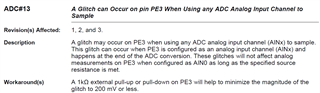

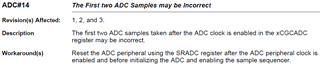

My output values is like this for 3.3 v input which I marked in yellow shades

please try to solve the issue