Other Parts Discussed in Thread: HALCOGEN

Hi,

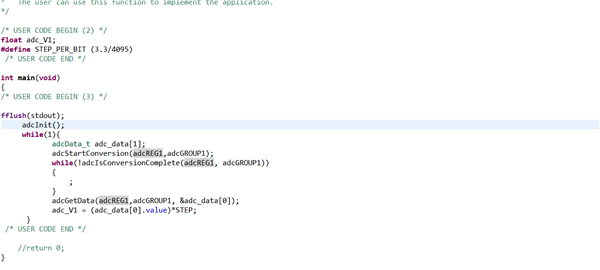

I am using RM44 ADC module to measure the Wheel speed sensor analog values , found that the actual analog value was supposed to be 1.6 volt (aprox) , but the adc value measured from the Micro controller is 1.1 volt.

1) Do i need to calibrate ADC at program initially to get the calibration value?

2) Do i need to use Sampling capacitor Discharge? if so what should be my sampling time?

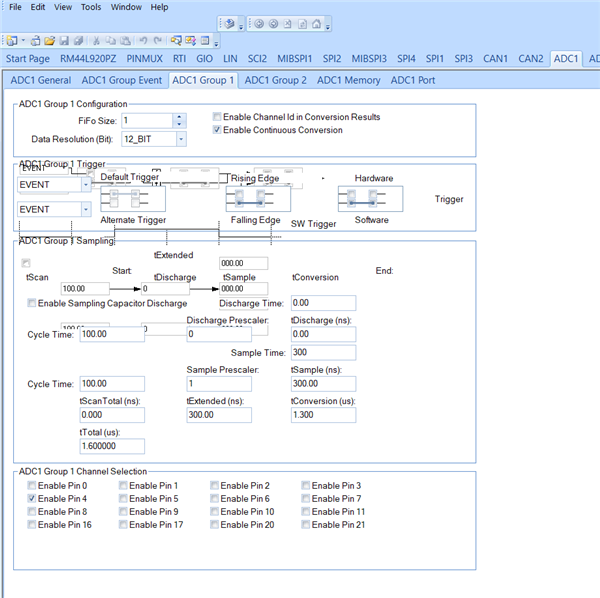

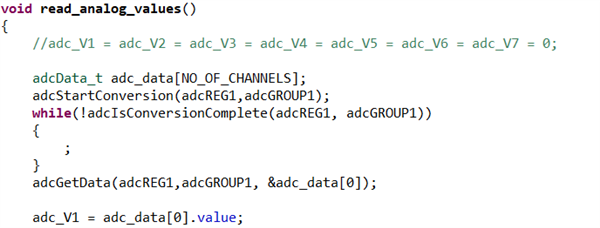

I am attaching my Code and Halcogen configurations: