Other Parts Discussed in Thread: EK-TM4C1294XL

Hi Team,

In this pwm example program .how to configer the different frequency.What is the max frequency can able to generate?

//*****************************************************************************

//

// pwm_dead_band.c - Example demonstrating the PWM dead-band generator.

//

// Copyright (c) 2019-2020 Texas Instruments Incorporated. All rights reserved.

// Software License Agreement

//

// Texas Instruments (TI) is supplying this software for use solely and

// exclusively on TI's microcontroller products. The software is owned by

// TI and/or its suppliers, and is protected under applicable copyright

// laws. You may not combine this software with "viral" open-source

// software in order to form a larger program.

//

// THIS SOFTWARE IS PROVIDED "AS IS" AND WITH ALL FAULTS.

// NO WARRANTIES, WHETHER EXPRESS, IMPLIED OR STATUTORY, INCLUDING, BUT

// NOT LIMITED TO, IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

// A PARTICULAR PURPOSE APPLY TO THIS SOFTWARE. TI SHALL NOT, UNDER ANY

// CIRCUMSTANCES, BE LIABLE FOR SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

// DAMAGES, FOR ANY REASON WHATSOEVER.

//

// This is part of revision 2.2.0.295 of the EK-TM4C1294XL Firmware Package.

//

//*****************************************************************************

#include <stdbool.h>

#include <stdint.h>

#include "inc/hw_memmap.h"

#include "driverlib/debug.h"

#include "driverlib/gpio.h"

#include "driverlib/pin_map.h"

#include "driverlib/pwm.h"

#include "driverlib/rom.h"

#include "driverlib/rom_map.h"

#include "driverlib/sysctl.h"

#include "driverlib/uart.h"

#include "utils/uartstdio.h"

//*****************************************************************************

//

//! \addtogroup pwm_examples_list

//! <h1>PWM Dead-band Generator Demo (pwm_dead_band)</h1>

//!

//! The example configures the PWM0 block to generate a 25% duty cycle signal

//! on PF2 with dead-band generation. This will produce a complement of PF2 on

//! PF3 (75% duty cycle). The dead-band generator is set to have a 10us delay

//! on the rising and falling edges of the PF2 PWM signal.

//!

//! This example uses the following peripherals and I/O signals.

//! - GPIO Port F peripheral (for PWM pins)

//! - M0PWM2 - PF2

//! - M0PWM3 - PF3

//!

//! UART0, connected to the Virtual Serial Port and running at 115,200, 8-N-1,

//! is used to display messages from this application.

//

//*****************************************************************************

//*****************************************************************************

//

// The variable g_ui32SysClock contains the system clock frequency in Hz.

//

//*****************************************************************************

uint32_t g_ui32SysClock;

//*****************************************************************************

//

// The error routine that is called if the driver library encounters an error.

//

//*****************************************************************************

#ifdef DEBUG

void

__error__(char *pcFilename, uint32_t ui32Line)

{

}

#endif

//*****************************************************************************

//

// Configure the UART and its pins. This must be called before UARTprintf().

//

//*****************************************************************************

void

ConfigureUART(void)

{

//

// Enable the GPIO Peripheral used by the UART.

//

MAP_SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOA);

//

// Enable UART0.

//

MAP_SysCtlPeripheralEnable(SYSCTL_PERIPH_UART0);

//

// Configure GPIO Pins for UART mode.

//

MAP_GPIOPinConfigure(GPIO_PA0_U0RX);

MAP_GPIOPinConfigure(GPIO_PA1_U0TX);

MAP_GPIOPinTypeUART(GPIO_PORTA_BASE, GPIO_PIN_0 | GPIO_PIN_1);

//

// Initialize the UART for console I/O.

//

UARTStdioConfig(0, 115200, g_ui32SysClock);

}

//*****************************************************************************

//

// Configure PWM for dead-band generation.

//

//*****************************************************************************

int

main(void)

{

uint32_t ui32PWMClockRate;

//

// Run from the PLL at 120 MHz.

// Note: SYSCTL_CFG_VCO_240 is a new setting provided in TivaWare 2.2.x and

// later to better reflect the actual VCO speed due to SYSCTL#22.

//

g_ui32SysClock = MAP_SysCtlClockFreqSet((SYSCTL_XTAL_25MHZ |

SYSCTL_OSC_MAIN |

SYSCTL_USE_PLL |

SYSCTL_CFG_VCO_240), 120000000);

//

// Initialize the UART.

//

ConfigureUART();

//

// Display the setup on the console.

//

UARTprintf("PWM ->\n");

UARTprintf(" Module: PWM0\n");

UARTprintf(" Pin(s): PF2 and PF3\n");

UARTprintf(" Features: Dead-band Generation\n");

UARTprintf(" Duty Cycle: 25%% on PF2 and 75%% on PF3\n");

UARTprintf(" Dead-band Length: 250 cycles\n\n");

//

// Enable the GPIO port that is used for the on-board LED.

//

MAP_SysCtlPeripheralEnable(SYSCTL_PERIPH_GPION);

//

// Enable the GPIO pin for the LED (PN0) as an output.

//

MAP_GPIOPinTypeGPIOOutput(GPIO_PORTN_BASE, GPIO_PIN_0);

//

// The PWM peripheral must be enabled for use.

//

MAP_SysCtlPeripheralEnable(SYSCTL_PERIPH_PWM0);

//

// Enable the GPIO port that is used for the PWM output.

//

MAP_SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOF);

//

// Configure the GPIO pad for PWM function on pins PF2 and PF3.

//

MAP_GPIOPinConfigure(GPIO_PF2_M0PWM2);

MAP_GPIOPinConfigure(GPIO_PF3_M0PWM3);

MAP_GPIOPinTypePWM(GPIO_PORTF_BASE, GPIO_PIN_2);

MAP_GPIOPinTypePWM(GPIO_PORTF_BASE, GPIO_PIN_3);

//

// Set the PWM clock to be SysClk / 8.

//

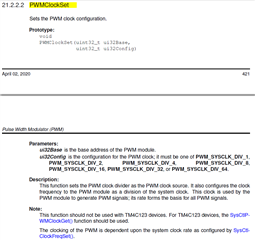

MAP_PWMClockSet(PWM0_BASE, PWM_SYSCLK_DIV_8);

//

// Use a local variable to store the PWM clock rate which will be

// 120 MHz / 8 = 15 MHz. This variable will be used to set the

// PWM generator period.

//

ui32PWMClockRate = g_ui32SysClock / 8;

//

// Configure PWM2 to count up/down without synchronization.

// Note: Enabling the dead-band generator automatically couples the 2

// outputs from the PWM block so we don't use the PWM synchronization.

//

MAP_PWMGenConfigure(PWM0_BASE, PWM_GEN_1,

PWM_GEN_MODE_UP_DOWN | PWM_GEN_MODE_NO_SYNC);

//

// Set the PWM period to 250Hz. To calculate the appropriate parameter

// use the following equation: N = (1 / f) * PWMClk. Where N is the

// function parameter, f is the desired frequency, and PWMClk is the

// PWM clock frequency based on the system clock.

//

MAP_PWMGenPeriodSet(PWM0_BASE, PWM_GEN_1, (ui32PWMClockRate / 250));

//

// Set PWM2 to a duty cycle of 25%. You set the duty cycle as a function

// of the period. Since the period was set above, you can use the

// PWMGenPeriodGet() function. For this example the PWM will be high for

// 25% of the time or (PWM Period / 4).

//

MAP_PWMPulseWidthSet(PWM0_BASE, PWM_OUT_2,

MAP_PWMGenPeriodGet(PWM0_BASE, PWM_GEN_1) / 4);

//

// Enable the dead-band generation on the PWM0 output signal. PWM bit 2

// (PF2), will have a duty cycle of 25% (set above) and PWM bit 3 will have

// a duty cycle of 75%. These signals will have a 10us gap between the

// rising and falling edges. This means that before PWM bit 3 goes high,

// PWM bit 2 has been low for at LEAST 10us. The same applies before

// PWM bit 2 goes high. The dead-band generator lets you specify the width

// of the "dead-band" delay, in PWM clock cycles, before the PWM signal

// goes high and after the PWM signal falls.

// For this example the PWM clock rate is 15 MHz, so we will use

// 150 cycles (150 cycles / 15MHz = 10us) on both the rising and falling

// edges of PF2. Reference the datasheet for more information on PWM

// dead-band generation.

//

MAP_PWMDeadBandEnable(PWM0_BASE, PWM_GEN_1, 150, 150);

//

// Enable the PWM Out Bit 2 (PF2) and Bit 3 (PF3) output signals.

//

MAP_PWMOutputState(PWM0_BASE, PWM_OUT_2_BIT | PWM_OUT_3_BIT, true);

//

// Enable the PWM generator block.

//

MAP_PWMGenEnable(PWM0_BASE, PWM_GEN_1);

//

// Loop forever blinking an LED while the PWM signals are generated.

//

while(1)

{

//

// Turn on the LED.

//

MAP_GPIOPinWrite(GPIO_PORTN_BASE, GPIO_PIN_0, GPIO_PIN_0);

//

// This function provides a means of generating a constant length

// delay. The function delay (in cycles) = 3 * parameter. Delay

// 0.5 seconds arbitrarily.

//

MAP_SysCtlDelay((g_ui32SysClock / 2) / 3);

//

// Turn off the LED.

//

MAP_GPIOPinWrite(GPIO_PORTN_BASE, GPIO_PIN_0, 0x00);

//

// This function provides a means of generating a constant length

// delay. The function delay (in cycles) = 3 * parameter. Delay

// 0.5 seconds arbitrarily.

//

MAP_SysCtlDelay((g_ui32SysClock / 2) / 3);

}

}

Thanks and regards

ARAVIND.S.R