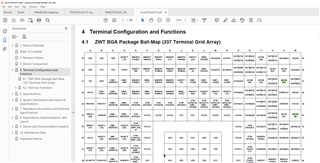

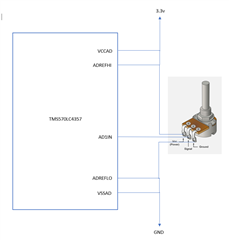

Part Number: TMS570LC4357

Other Parts Discussed in Thread: HALCOGEN

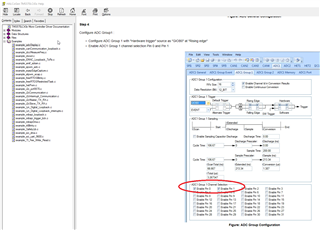

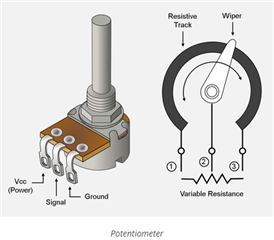

Iam working on ADC using controller tms570ls4357 , for that i need to give analog input to channel , what type of analog should be given , how its done , can u help me sir , from which register data will be stored .

thank you ,

jeeva