Other Parts Discussed in Thread: EK-TM4C1294XL

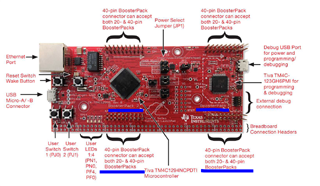

I am thinking somebody has asked a question like this before, but I searched and didn't find anything. I've been using the TM4C129X Development Board to interface with our controller board and update firmware. Now I'm trying to use the TM4C1294 Connected Launchpad Evaluation Kit (EK-TM4C1294XL). I know which connector to use and the proper orientation for the interface cable to connect to our board. How do I know which connector to use and the proper orientation on the Evaluation Kit board?