Other Parts Discussed in Thread: HALCOGEN

Hello,

How do I create a NHET digital loopback?

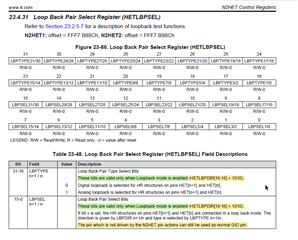

HalCoGen creates PWM functions with 1 pin each and Capture functions with 2 pins each. The Loop Back Pair Select Register (HETLBPSEL) and Loop Back Pair Direction Register (HETLBPDIR) configure pairs of consecutive pins (HET[n] and HET[n+1]).

Regards,

Marcio.