Other Parts Discussed in Thread: SYSCONFIG

Tool/software:

Hi,

In my application, in order to improve the frequency measurement stability with temperature variations I enabled the Frequency Correction Loop functionality by calling this function right after the main code start.

DL_SYSCTL_enableSYSOSCFCL();

At hardware level, the frequency correction loop (FCL) circuit utilizes an external 100-kΩ resistor, populated between the ROSC pin and VSS. I assembled it.

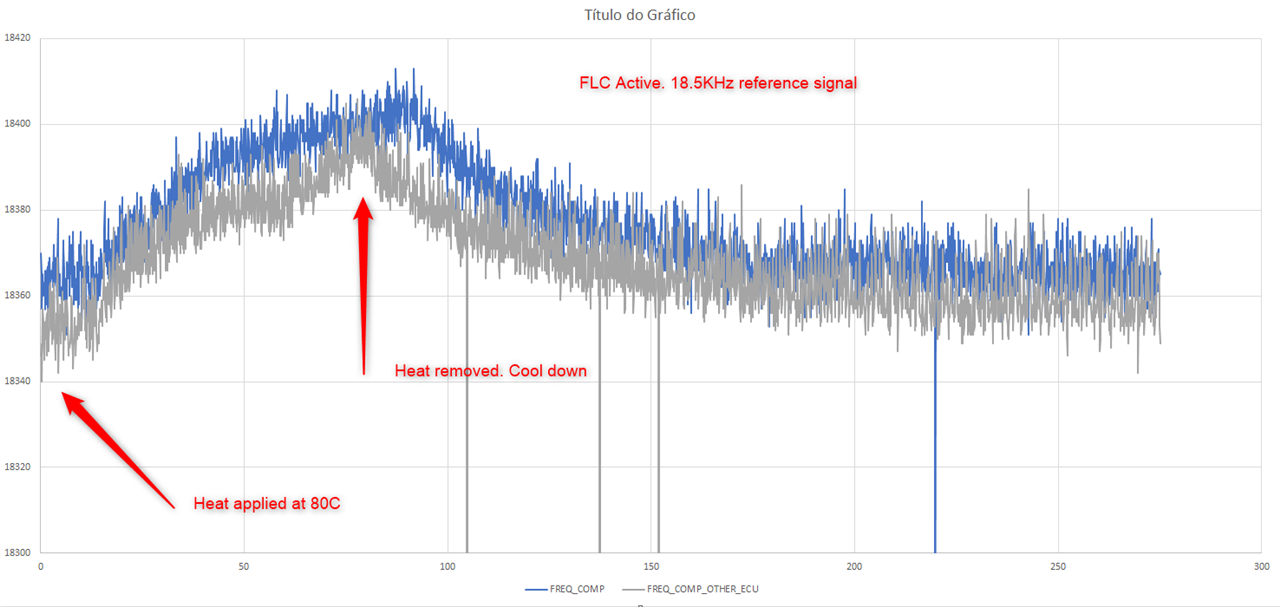

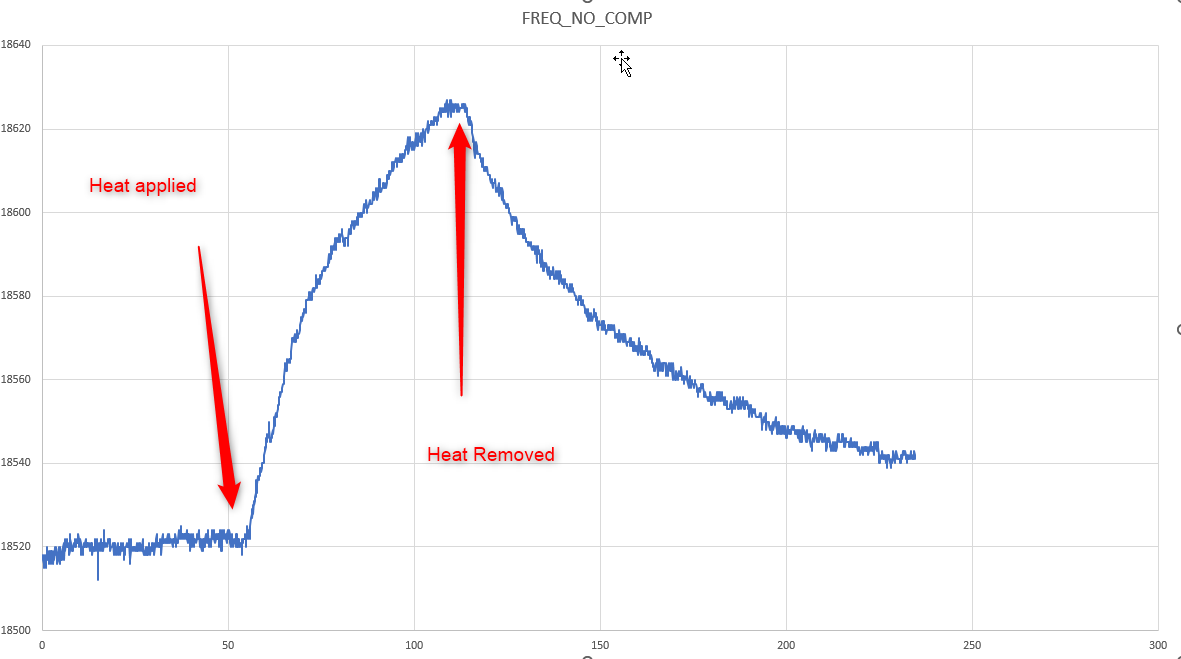

To verify the functionality, I exposed the MCU to a heat gun configured to 80'C and observed the behavior of the measurement of a fixed frequency input channel with FCL active and without.

What I observed was:

-FCL reduces significantly the measurement variation with the heating process comparatively to the scenario without its activation.

-FCL introduces a relevant offset at ambient temperature frequency measurement comparatively to the condition where it is not active (around140Hz)

I performed this test with two different systems, with the same result.

What is the maximum admissible tolerance for this resistor? Are these results in line with a core frequency of 32MHz and a 1% tolerance resistor?

Thanks for the support