Tool/software:

Hi,

My customer has some questions in the app note of AM243x/AM64x Single Chip Servo Motor Control Implementation and Benchmark (sprad03 – March 2022).

Could you answer their questions below ?

1. Processing time

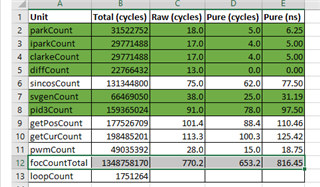

Is the CPU processing time for control period the total of Open Loop Id/Iq, Closed Loop Id/Iq, Closed Loop Speed, Closed Loop Position and Closed Loop CiA402 ?

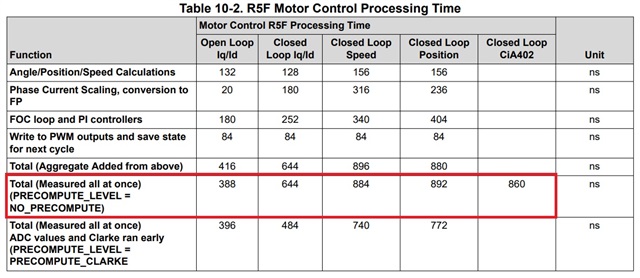

2. Difference between Table 10-2 and Table 14-5

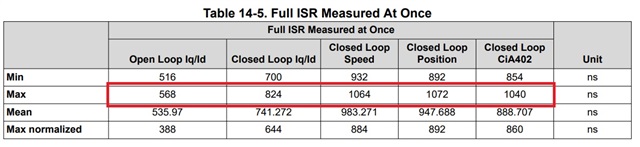

There are Table 10-2 and 14-5. Do the numbers in Table 10-2 come from the Max normalized in Table 14-5 ?

If the customer wants to know the maximum value of CPU processing for control period, they should summate all of Max values in Table 14-5 ?

It would be 4568 [ns] ?

3. Difference between Min and Max

In the Table 14-5, there are Min an Max value. Could you tell them what the factor is for these differences ?

4. Update

This app note looks old, issued in 2022. Do you have any update or improvement in this benchmark ?

Thanks and regards,

Hideaki