Other Parts Discussed in Thread: HALCOGEN

Tool/software:

Dear All.

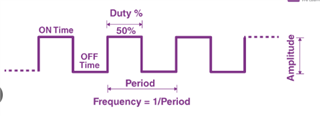

As the title says, I want to use the N2HET1[31] pin of tms570ls3137 as a PWM pin to send data to the FPGA.

I enabled HET1->Pwm0-7 -> PWM0 for the Halcogen of tms570ls3137, and set the HET pin to 31.

And I called and executed the PWM API as follows.

pwmStart(hetRAM1, pwm0);

for(uint8 i = 0; i < size; i++){

pwmSetDuty(hetRAM1, pwm0, test_telegram_table[id].data[i]);

}

pwmStop(hetRAM1, pwm0);

Actually, this seems to be the end for tms570ls3137,

but the problem is that I don't know how to implement it in FPGA.

1. If I do it according to the example source above, will the data go out as a PWM signal from tms570?

2. How do I recognize PWM data in FPGA?

Do you have something like a PWM datasheet?

It's a bit difficult because I have to implement it again according to the tms570 specifications in FPGA.

Can you help me?

Best Regards,

IBLEE