Part Number: MSPM0L1305

Tool/software:

Hi Champs,

I am asking this for our customer.

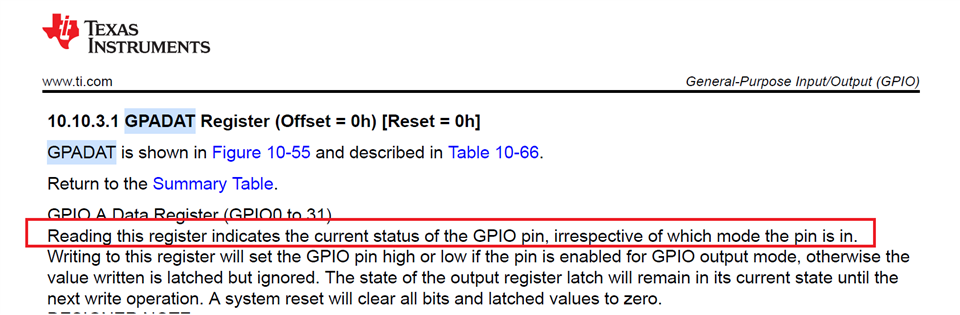

When using capture, is there any register/driverlib API to know if the input signal is kept in high or low?

For example, if the input PWM signal is 100% duty or 0% duty. How does MSPM0 capture it?

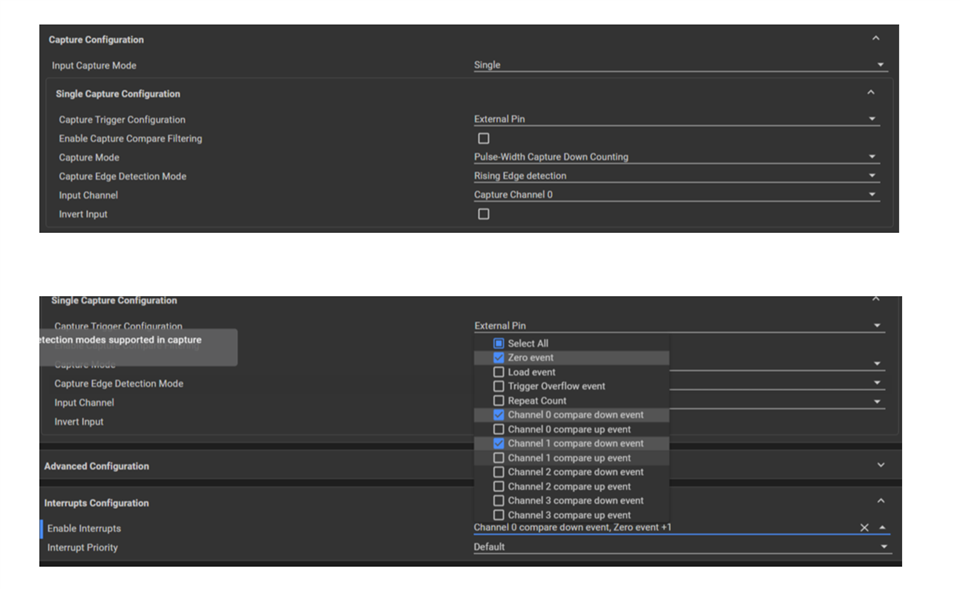

The user's setting like below.