Tool/software:

Dear TI Experts

According to Heidenhain document (D1128897 - 03 - A - 02 8) - Safety with EnDat 2.2 and Non-Safe

EnDat Master

section 3.5.2 Counter for measuring the recovery time I

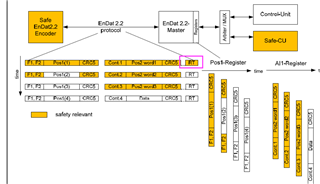

The recovery time can, for example, be measured by a counter realized within the EnDat master. The

last rising edge of the EnDat-Clock (positive signal) indicates the starting trigger and the following falling

edge of the EnDat-Data (positive signal) indicates the stop trigger for the recovery time I counter. (The

EnDat 2.2 protocol has to be analyzed within the master to obtain the correct trigger time. Also, the cable

delay has to be taken into account.)

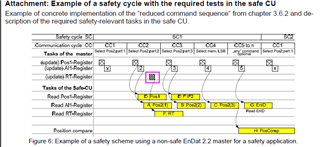

The counter value has to be provided in a dedicated RT register at the interface of the master. The

counter and the RT register have to change dynamically in normal operation mode to detect “stuck-at”

errors of counter and RT register. This can be realized with a counter that does not reset. Therefore the

expected value for the recovery time is coded in the difference between the last and the current value.

The last value has to be stored in the safe CU.

For high efficiency fault detection (especially for multi-masters) it is necessary to load the counters of

different axes with different starting values. The difference has to be at least double the expected tolerance

range of the recovery time. Due to this and the incrementing values a forced dynamic sampling of

the counter is not necessary.

1) Section 3.5.2 specifies of a counter that does not reset as a means of RT implementation to meet "stuck at" detection requirement.

I can's seems to find "Non reset RT counter" in the endat interface.

Would you be be able to provide "non reset RT counter" as part of endat interface

Thank you

Alan I