Tool/software:

Hello;

I have been working with single chip servo example for AM243-Lp board. (/ti/motor_control_sdk_am243x_09_02_00_09/examples/tidep_01032_dual_motor_drive/single_chip_servo/am243x-lp/).

There is no problem when I run it while EPWM freq is 50khz. But I need to have 64 EPWM frequency and I change only the line of (appEpwmCfg.epwmOutFreq = gEpwmOutFreq;) in init_pwms() method.

gEpwmOutFreq is ( 1U * 64000U) in my code instead of ( 1U * 50000U) . This line assign EPW output frequency in init method.

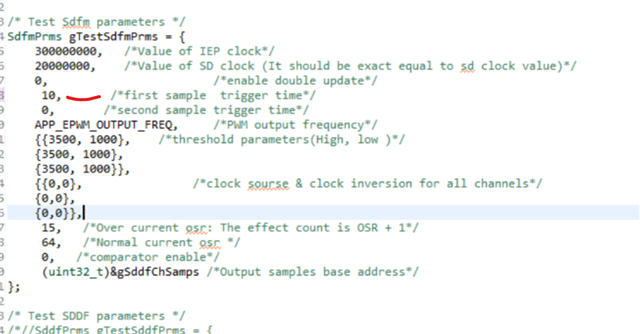

This is not sufficient to make motor is rotating. I supposed that I need to change more things. For example some of SDFM parameters.

How can you help me to change the EPWM frequency in the single chip servo project?

Regards

Kadir