Other Parts Discussed in Thread: INA240, CDCV304

Tool/software:

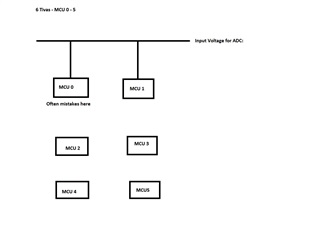

In a two-channel system A and B, with three TM4C123BH6 (BGA 157) per channel measure analog signals.

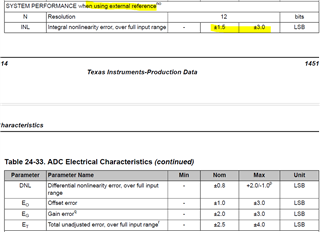

Measuring current of max. 3A, it is an accuracy of 0.1% deviation between the channels and against an external measurement required.

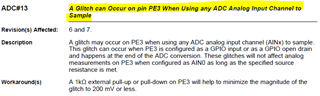

We have a problem with the ADC inputs. For example A0_I on MCU0 (PD5) measures 3 to 5 digits wrong. All other ADC imputs on this MCU have the same behaviour.

It's sporadically, tempereture has no impact and when the failure occures it is constant till the next restart.

The test software is as minimal as possible. The ADC and two GPIOs with LEDs there are configured.

|

|

|

|

The electrical design is not perfect, but the placement is almost identical, only the routing is different.

- Instead of the max. 4µF at the digital supply VDD, a single X7R 4.7µF capacitor (C455) is installed.

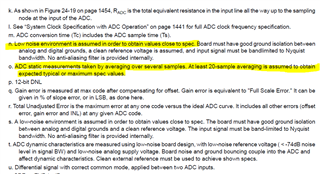

- VREFA+ is supplied by an external reference source with 3.3V and 0.1% tolerance via a ferrite bead and the recommended block capacitors.

- A voltage from a current generated by an INA240 is applied to the ADC input via a pull-down of 10k Ohm (R472), which is fed through a low-pass filter with 10k Ohm (R504) and 100nF (C472).

According to application note SPNA061, Cext should have approx. 40 nF (C106) and Rsource 410 Ohm (R504).

Chances in the component values doesn’t show any improvement.

For measurement purposes, the INA240 was disconnected and a external voltage source with low ripple was applied. This also shows a difference between the channels.

If the ADC input is open, there can be measured some 10 millivolts that are higher to other MCUs and ADC inputs.

Could this be crosstalk?