Tool/software:

I am having trouble seeing the I2C SDA and SCL signals on my EK-TM4C123GXL Launchpad using example code.

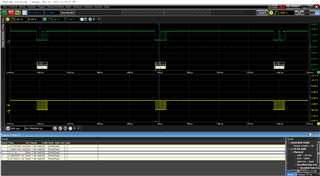

I have pins PB2 on CH1 and PB3 on CH2.

Both PB2 and PB3 are connected to 1.5k pull up resistors.

Below is the code I am using,

//*****************************************************************************

//

// master_slave_loopback.c - Example demonstrating a simple I2C message

// transmission and reception.

//

// Copyright (c) 2010-2020 Texas Instruments Incorporated. All rights reserved.

// Software License Agreement

//

// Redistribution and use in source and binary forms, with or without

// modification, are permitted provided that the following conditions

// are met:

//

// Redistributions of source code must retain the above copyright

// notice, this list of conditions and the following disclaimer.

//

// Redistributions in binary form must reproduce the above copyright

// notice, this list of conditions and the following disclaimer in the

// documentation and/or other materials provided with the

// distribution.

//

// Neither the name of Texas Instruments Incorporated nor the names of

// its contributors may be used to endorse or promote products derived

// from this software without specific prior written permission.

//

// THIS SOFTWARE IS PROVIDED BY THE COPYRIGHT HOLDERS AND CONTRIBUTORS

// "AS IS" AND ANY EXPRESS OR IMPLIED WARRANTIES, INCLUDING, BUT NOT

// LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

// A PARTICULAR PURPOSE ARE DISCLAIMED. IN NO EVENT SHALL THE COPYRIGHT

// OWNER OR CONTRIBUTORS BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL,

// SPECIAL, EXEMPLARY, OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT

// LIMITED TO, PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES; LOSS OF USE,

// DATA, OR PROFITS; OR BUSINESS INTERRUPTION) HOWEVER CAUSED AND ON ANY

// THEORY OF LIABILITY, WHETHER IN CONTRACT, STRICT LIABILITY, OR TORT

// (INCLUDING NEGLIGENCE OR OTHERWISE) ARISING IN ANY WAY OUT OF THE USE

// OF THIS SOFTWARE, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.

//

// This is part of revision 2.2.0.295 of the Tiva Firmware Development Package.

//

//*****************************************************************************

#include <stdbool.h>

#include <stdint.h>

#include "inc/hw_i2c.h"

#include "inc/hw_memmap.h"

#include "inc/hw_types.h"

#include "driverlib/gpio.h"

#include "driverlib/i2c.h"

#include "driverlib/pin_map.h"

#include "driverlib/sysctl.h"

#include "driverlib/uart.h"

#include "utils/uartstdio.h"

//*****************************************************************************

//

//! \addtogroup i2c_examples_list

//! <h1>I2C Master Loopback (i2c_master_slave_loopback)</h1>

//!

//! This example shows how to configure the I2C0 module for loopback mode.

//! This includes setting up the master and slave module. Loopback mode

//! internally connects the master and slave data and clock lines together.

//! The address of the slave module is set in order to read data from the

//! master. Then the data is checked to make sure the received data matches

//! the data that was transmitted. This example uses a polling method for

//! sending and receiving data.

//!

//! This example uses the following peripherals and I/O signals. You must

//! review these and change as needed for your own board:

//! - I2C0 peripheral

//! - GPIO Port B peripheral (for I2C0 pins)

//! - I2C0SCL - PB2

//! - I2C0SDA - PB3

//!

//! The following UART signals are configured only for displaying console

//! messages for this example. These are not required for operation of I2C.

//! - UART0 peripheral

//! - GPIO Port A peripheral (for UART0 pins)

//! - UART0RX - PA0

//! - UART0TX - PA1

//!

//! This example uses the following interrupt handlers. To use this example

//! in your own application you must add these interrupt handlers to your

//! vector table.

//! - None.

//

//*****************************************************************************

//*****************************************************************************

//

// Number of I2C data packets to send.

//

//*****************************************************************************

#define NUM_I2C_DATA 3

//*****************************************************************************

//

// Set the address for slave module. This is a 7-bit address sent in the

// following format:

// [A6:A5:A4:A3:A2:A1:A0:RS]

//

// A zero in the "RS" position of the first byte means that the master

// transmits (sends) data to the selected slave, and a one in this position

// means that the master receives data from the slave.

//

//*****************************************************************************

#define SLAVE_ADDRESS 0x3C

//*****************************************************************************

//

// This function sets up UART0 to be used for a console to display information

// as the example is running.

//

//*****************************************************************************

void

InitConsole(void)

{

//

// Enable GPIO port A which is used for UART0 pins.

// TODO: change this to whichever GPIO port you are using.

//

SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOA);

//

// Configure the pin muxing for UART0 functions on port A0 and A1.

// This step is not necessary if your part does not support pin muxing.

// TODO: change this to select the port/pin you are using.

//

GPIOPinConfigure(GPIO_PA0_U0RX);

GPIOPinConfigure(GPIO_PA1_U0TX);

//

// Enable UART0 so that we can configure the clock.

//

SysCtlPeripheralEnable(SYSCTL_PERIPH_UART0);

//

// Use the internal 16MHz oscillator as the UART clock source.

//

UARTClockSourceSet(UART0_BASE, UART_CLOCK_PIOSC);

//

// Select the alternate (UART) function for these pins.

// TODO: change this to select the port/pin you are using.

//

GPIOPinTypeUART(GPIO_PORTA_BASE, GPIO_PIN_0 | GPIO_PIN_1);

//

// Initialize the UART for console I/O.

//

UARTStdioConfig(0, 115200, 16000000);

}

//*****************************************************************************

//

// Configure the I2C0 master and slave and connect them using loopback mode.

//

//*****************************************************************************

int

main(void)

{

#if defined(TARGET_IS_TM4C129_RA0) || \

defined(TARGET_IS_TM4C129_RA1) || \

defined(TARGET_IS_TM4C129_RA2)

uint32_t ui32SysClock;

#endif

uint32_t pui32DataTx[NUM_I2C_DATA];

uint32_t pui32DataRx[NUM_I2C_DATA];

uint32_t ui32Index;

//

// Set the clocking to run directly from the external crystal/oscillator.

// TODO: The SYSCTL_XTAL_ value must be changed to match the value of the

// crystal on your board.

//

#if defined(TARGET_IS_TM4C129_RA0) || \

defined(TARGET_IS_TM4C129_RA1) || \

defined(TARGET_IS_TM4C129_RA2)

ui32SysClock = SysCtlClockFreqSet((SYSCTL_XTAL_25MHZ |

SYSCTL_OSC_MAIN |

SYSCTL_USE_OSC), 25000000);

#else

SysCtlClockSet(SYSCTL_SYSDIV_1 | SYSCTL_USE_OSC | SYSCTL_OSC_MAIN |

SYSCTL_XTAL_16MHZ);

#endif

//

// The I2C0 peripheral must be enabled before use.

//

SysCtlPeripheralEnable(SYSCTL_PERIPH_I2C0);

//

// For this example I2C0 is used with PortB[3:2]. The actual port and

// pins used may be different on your part, consult the data sheet for

// more information. GPIO port B needs to be enabled so these pins can

// be used.

// TODO: change this to whichever GPIO port you are using.

//

SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOB);

//

// Configure the pin muxing for I2C0 functions on port B2 and B3.

// This step is not necessary if your part does not support pin muxing.

// TODO: change this to select the port/pin you are using.

//

GPIOPinConfigure(GPIO_PB2_I2C0SCL);

GPIOPinConfigure(GPIO_PB3_I2C0SDA);

//

// Select the I2C function for these pins. This function will also

// configure the GPIO pins pins for I2C operation, setting them to

// open-drain operation with weak pull-ups. Consult the data sheet

// to see which functions are allocated per pin.

// TODO: change this to select the port/pin you are using.

//

GPIOPinTypeI2CSCL(GPIO_PORTB_BASE, GPIO_PIN_2);

GPIOPinTypeI2C(GPIO_PORTB_BASE, GPIO_PIN_3);

//

// Enable loopback mode. Loopback mode is a built in feature that is

// useful for debugging I2C operations. It internally connects the I2C

// master and slave terminals, which effectively let's you send data as

// a master and receive data as a slave.

// NOTE: For external I2C operation you will need to use external pullups

// that are stronger than the internal pullups. Refer to the datasheet for

// more information.

//

//I2CLoopbackEnable(I2C0_BASE);

//

// Enable and initialize the I2C0 master module. Use the system clock for

// the I2C0 module. The last parameter sets the I2C data transfer rate.

// If false the data rate is set to 100kbps and if true the data rate will

// be set to 400kbps. For this example we will use a data rate of 100kbps.

//

#if defined(TARGET_IS_TM4C129_RA0) || \

defined(TARGET_IS_TM4C129_RA1) || \

defined(TARGET_IS_TM4C129_RA2)

I2CMasterInitExpClk(I2C0_BASE, ui32SysClock, false);

#else

I2CMasterInitExpClk(I2C0_BASE, SysCtlClockGet(), false);

#endif

//

// Enable the I2C0 slave module. This module is enabled only for testing

// purposes. It does not need to be enabled for proper operation of the

// I2Cx master module.

//

I2CSlaveEnable(I2C0_BASE);

//

// Set the slave address to SLAVE_ADDRESS. In loopback mode, it's an

// arbitrary 7-bit number (set in a macro above) that is sent to the

// I2CMasterSlaveAddrSet function.

//

I2CSlaveInit(I2C0_BASE, SLAVE_ADDRESS);

//

// Tell the master module what address it will place on the bus when

// communicating with the slave. Set the address to SLAVE_ADDRESS

// (as set in the slave module). The receive parameter is set to false

// which indicates the I2C Master is initiating a writes to the slave. If

// true, that would indicate that the I2C Master is initiating reads from

// the slave.

//

I2CMasterSlaveAddrSet(I2C0_BASE, SLAVE_ADDRESS, false);

//

// Set up the serial console to use for displaying messages. This is

// just for this example program and is not needed for I2C operation.

//

InitConsole();

//

// Display the example setup on the console.

//

UARTprintf("I2C Loopback Example ->");

UARTprintf("\n Module = I2C0");

UARTprintf("\n Mode = Single Send/Receive");

UARTprintf("\n Rate = 100kbps\n\n");

//

// Initalize the data to send.

//

pui32DataTx[0] = 'I';

pui32DataTx[1] = '2';

pui32DataTx[2] = 'C';

//

// Initalize the receive buffer.

//

for(ui32Index = 0; ui32Index < NUM_I2C_DATA; ui32Index++)

{

pui32DataRx[ui32Index] = 0;

}

//

// Indicate the direction of the data.

//

UARTprintf("Tranferring from: Master -> Slave\n");

//

// Send 3 peices of I2C data from the master to the slave.

//

for(;;)

{

for(ui32Index = 0; ui32Index < NUM_I2C_DATA; ui32Index++)

{

//

// Display the data that the I2C0 master is transferring.

//

UARTprintf(" Sending: '%c' . . . ", pui32DataTx[ui32Index]);

//

// Place the data to be sent in the data register

//

I2CMasterDataPut(I2C0_BASE, pui32DataTx[ui32Index]);

//

// Initiate send of data from the master. Since the loopback

// mode is enabled, the master and slave units are connected

// allowing us to receive the same data that we sent out.

//

I2CMasterControl(I2C0_BASE, I2C_MASTER_CMD_SINGLE_SEND);

//

// Wait until the slave has received and acknowledged the data.

//

//hile(!(I2CSlaveStatus(I2C0_BASE) & I2C_SLAVE_ACT_RREQ))

//{

//}

//

// Read the data from the slave.

//

// pui32DataRx[ui32Index] = I2CSlaveDataGet(I2C0_BASE);

//

// Wait until master module is done transferring.

//

while(I2CMasterBusy(I2C0_BASE))

{

}

//

// Display the data that the slave has received.

//

//UARTprintf("Received: '%c'\n", pui32DataRx[ui32Index]);

}

}

//

// Reset receive buffer.

//

for(ui32Index = 0; ui32Index < NUM_I2C_DATA; ui32Index++)

{

pui32DataRx[ui32Index] = 0;

}

//

// Indicate the direction of the data.

//

UARTprintf("\n\nTranferring from: Slave -> Master\n");

//

// Modifiy the data direction to true, so that seeing the address will

// indicate that the I2C Master is initiating a read from the slave.

//

I2CMasterSlaveAddrSet(I2C0_BASE, SLAVE_ADDRESS, true);

//

// Do a dummy receive to make sure you don't get junk on the first receive.

//

I2CMasterControl(I2C0_BASE, I2C_MASTER_CMD_SINGLE_RECEIVE);

//

// Dummy acknowledge and wait for the receive request from the master.

// This is done to clear any flags that should not be set.

//

while(!(I2CSlaveStatus(I2C0_BASE) & I2C_SLAVE_ACT_TREQ))

{

}

for(ui32Index = 0; ui32Index < NUM_I2C_DATA; ui32Index++)

{

//

// Display the data that I2C0 slave module is transferring.

//

UARTprintf(" Sending: '%c' . . . ", pui32DataTx[ui32Index]);

//

// Place the data to be sent in the data register

//

I2CSlaveDataPut(I2C0_BASE, pui32DataTx[ui32Index]);

//

// Tell the master to read data.

//

I2CMasterControl(I2C0_BASE, I2C_MASTER_CMD_SINGLE_RECEIVE);

//

// Wait until the slave is done sending data.

//

while(!(I2CSlaveStatus(I2C0_BASE) & I2C_SLAVE_ACT_TREQ))

{

}

//

// Read the data from the master.

//

pui32DataRx[ui32Index] = I2CMasterDataGet(I2C0_BASE);

//

// Display the data that the slave has received.

//

UARTprintf("Received: '%c'\n", pui32DataRx[ui32Index]);

}

//

// Tell the user that the test is done.

//

UARTprintf("\nDone.\n\n");

//

// Return no errors

//

return(0);

}

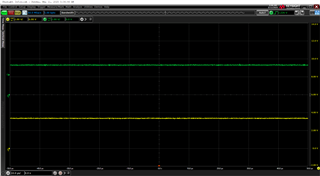

Both CH1 and CH2 both stay at 3.3V constantly even when sending "I2C" constantly.

Thanks,

Allan