Tool/software:

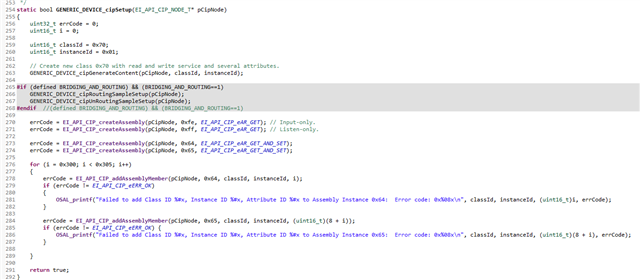

To create a 4-byte counter (e.g., uint32_t) on the LP-AM243 that:

-

Increments on a condition (e.g., button press, timer, signal)

-

Is exposed via EtherNet/IP Input Assembly (e.g., Assembly 101)

-

Stored in memory so CODESYS or Allen-Bradley can read it via EDS

-

Compatible with the EDS parameter / assembly model