Hi there,

I finally got the chance today to test my recently purchased BOOSTXL-SENSHUB on a new, fresh out of the box EK-LM4F120XL Stellaris Launchpad.

When testing all the samples provided I found that three of them were not working:

- Airmouse --> maybe related to my setup since I'm running CCS in an VMware Virtual machine (win7) on a MAC OS X host

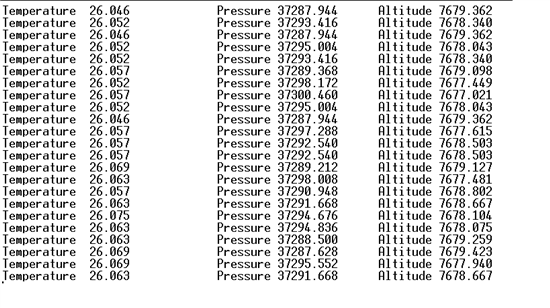

- BMP180 pressure sensor demo --> no air pressure! Don't worry: I'm still alive although there seems to be no air for me to breathe.

- MPU-9150 --> no MAG data --> no Euler Angles/Quaternations. Board is sitting flat on the table when capturing the screenshot (refer to z-axis value = roughly 1g).

All other demos seems to run fine (on first view).

All examples should run on the EK-LM4F120XL without any modifications, right?

Do you have any other software to verify correct sensor/board operation (i.e. from factory end test)?

Is there a list of the I2C addresses in use? A scan with my quick&dirty I2C address scanner (part of my Stellaris I2C API, a polled I2C driver which can i.e. be found here http://e2e.ti.com/support/microcontrollers/tiva_arm/f/908/t/238721.aspx) gives me the list below:

0x77 --> BMP180

0x68 --> GYRO/ACC part of MPU-9150 - MAG is connected to the Auxiliary I2C bus of the MPU-9150 --> can not acknowledge until initialized for operation

0x44 --> ISL29023

0x41 --> TMP006

0x40 --> SHT21

0x00 --> unknown (?)

I have no glue which sensor also acknowledges address 0x00! Any idea?

Thank you for your answer! Hopefully I've not received a $49.99 brick!

Kind regards

aBUGSworstnightmare