Hello!

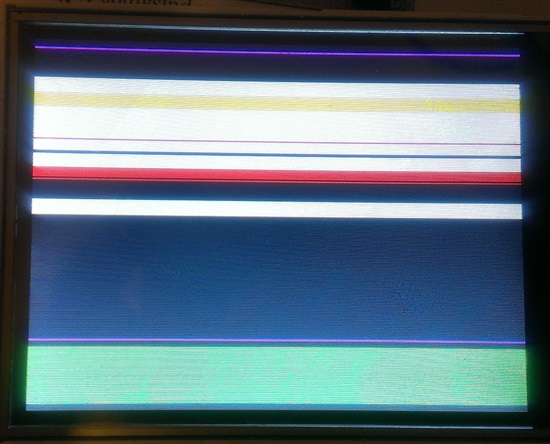

i am the designer of LCDBPV2 ( http://danirebollo.es/index.php/bundles/lcd-bp-v2 ) and i sent it to promote in http://www.ti.com/ww/en/launchpad/boosterpacks.html . while i'm waiting, i'm fixing some code on my library.

It works very well with my libraries but i would like to use Texas Instruments Graphics library because widgets and more, so:

In my first version of this LCD boosterpack, it was totally compatible because all pinout are the same and connect touch with microcontroller directly, but in second version i use TSC2007.

I successfully initialize them and i get position on the screen with interrupts but now i would like to intercept TI Graphic Library (touch.c) to give my data and make it work.

I looked to "touch.c" and i found that "g_sTouchX" and "g_sTouchY" stores "x" and "y" data. i get some conclussions (maybe wrong...):

-"TouchScreenIntHandler()" runs when every ADC sample is adquired and set "g_sTouchX" and "g_sTouchY" raw data. Later "TouchScreenDebouncer()" reads "g_sTouchX" and "g_sTouchY" data and updates all framework (widgets, buttons...).

-"g_sTouchX" and "g_sTouchY" are external variables, so i can change his value in main. "TouchScreenIntHandler()" and "TouchScreenDebouncer()" are extrnal functions, so i can call to it in main.

I comment these lines to delete ADC interrupt: "ADCIntEnable(ADC0_BASE, 3); IntEnable(INT_ADC3);" and, in main, i put my touch values on "g_sTouchX" and "g_sTouchY" variables and later call to "TouchScreenDebouncer()" , but wont work...

can you tell me if i need to call to another function to get it works?

thanx.