Other Parts Discussed in Thread: TM4C123BH6PM

Hi, I'm using QEI in order to count a rotation of a remote car's wheel.

I connected a digital hall sensor output to QEI module 1's input A(PHA1/PC5, capture mode : Only PhA).

The hall sensor is WSH131-XPAN3.

(Datasheet link : http://pdf1.alldatasheet.co.kr/datasheet-pdf/view/227165/WINSON/WSH131-XPAN3.html )

Attaching a magnet to the wheel, the pulse comes out well.

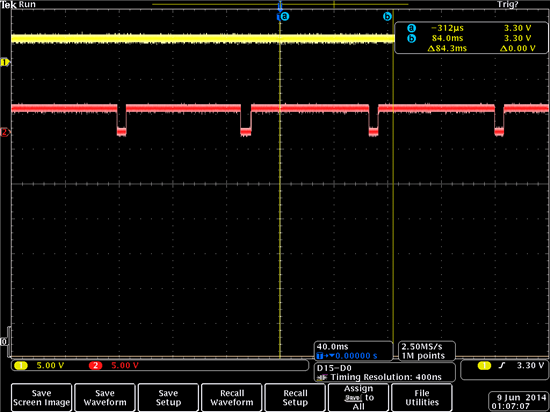

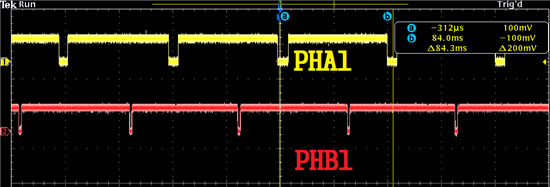

The yellow pulse is the IDX1. It is constantly digital '1'.

The red pulse is PHA1. The hall sensor's output is 0 when there is a manget in front.

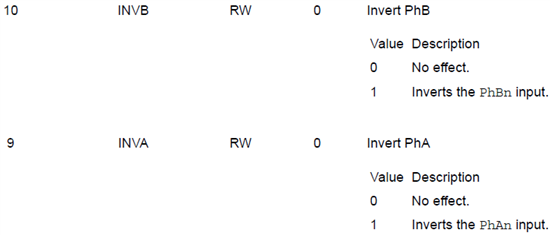

Due to the hall sensor's output, I used the invert mode.

(reference : TM4C123BH6PM datasheet, 1186pg)

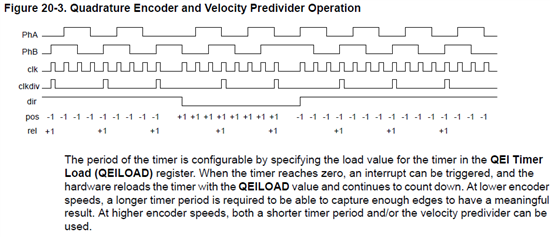

However, when I read the QEI position register, it doesn't increase as i expected.

For some reason, it looked like it was reset.

The IDX1 and PHB1 pin is not connected to anything. What might be the problem..?

This is the source code I made. It is a code about printing the qei position to the terminal.

Always thanks to your help.

-Regards, Min-Ku