Hi,

I have built a timer triggered ADC program to read 4 different channel using sequencer 1. I am checking values in watch window in debug mode. While the ADC is measuring values properly, channels are getting swapped. Here is the code:

#include <stdint.h>

#include <stdbool.h>

#include <math.h>

#include "inc/tm4c123gh6pm.h"

#include "inc/hw_memmap.h"

#include "inc/hw_types.h"

#include "driverlib/sysctl.h"

#include "driverlib/interrupt.h"

#include "driverlib/gpio.h"

#include "driverlib/timer.h"

#include "driverlib/adc.h"

#include "driverlib/fpu.h"

#include "driverlib/pin_map.h"

uint32_t ui32ADC0Value[4];

volatile uint32_t a,b,c,d;

int main(void)

{

//Set processor @ 80 MHz.

SysCtlClockSet(SYSCTL_SYSDIV_2_5|SYSCTL_USE_PLL|SYSCTL_XTAL_16MHZ|SYSCTL_OSC_MAIN);

//===============================================================================================

//Give clock to the peripherals:

//GPIO for testing: LED: R B G

SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOF);

//GPIO for capture interrupt

SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOC);

//ADC pins

SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOE);

SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOD);

//Timer for 40 kHz calc and adc trigger

SysCtlPeripheralEnable(SYSCTL_PERIPH_TIMER0);

//ADC 0

SysCtlPeripheralEnable(SYSCTL_PERIPH_ADC0);

SysCtlDelay(10);

//===============================================================================================

//Peripheral configuration

//Config GPIO: LED R B G

GPIOPinTypeGPIOOutput(GPIO_PORTF_BASE, GPIO_PIN_1|GPIO_PIN_2|GPIO_PIN_3);

//Config Timer0: 40 kHz

TimerConfigure(TIMER0_BASE, TIMER_CFG_PERIODIC); //32 bit mode

TimerLoadSet(TIMER0_BASE, TIMER_A, 2000-1); //load period

IntEnable(INT_TIMER0A); //interrupt enable

TimerIntEnable(TIMER0_BASE, TIMER_TIMA_TIMEOUT); //interrupt condition: timeout

TimerControlTrigger(TIMER0_BASE, TIMER_A, true); //ADC trigger

//Configure ADC0

ADCSequenceDisable(ADC0_BASE, 1);

GPIOPinTypeADC(GPIO_PORTE_BASE, GPIO_PIN_0);

GPIOPinTypeADC(GPIO_PORTE_BASE, GPIO_PIN_1);

GPIOPinTypeADC(GPIO_PORTE_BASE, GPIO_PIN_2);

GPIOPinTypeADC(GPIO_PORTE_BASE, GPIO_PIN_3);

GPIOPinTypeADC(GPIO_PORTD_BASE, GPIO_PIN_3);

ADCSequenceConfigure(ADC0_BASE, 1, ADC_TRIGGER_TIMER, 0); //sequencer 1, proccessor trig, priority zero highest

ADCSequenceStepConfigure(ADC0_BASE, 1, 0, ADC_CTL_CH4);

ADCSequenceStepConfigure(ADC0_BASE, 1, 1, ADC_CTL_CH3);

ADCSequenceStepConfigure(ADC0_BASE, 1, 2, ADC_CTL_CH2);

ADCSequenceStepConfigure(ADC0_BASE, 1, 3, ADC_CTL_CH1|ADC_CTL_IE|ADC_CTL_END); //final step: give int, stop

IntEnable(INT_ADC0SS1);

ADCIntClear(ADC0_BASE, 1);

ADCIntEnable(ADC0_BASE, 1);

//===============================================================================================

//Enable the peripherals one by one

//Int master enable

IntMasterEnable();

//Timer0: Calc & ADC trigger

TimerEnable(TIMER0_BASE, TIMER_A);

//ADC

ADCSequenceEnable(ADC0_BASE, 1);

//===============================================================================================

while(1)

{

}

}

//===============================================================================================

void Timer0IntHandler(void)

{

TimerIntClear(TIMER0_BASE, TIMER_TIMA_TIMEOUT);

if(GPIOPinRead(GPIO_PORTC_BASE, GPIO_PIN_4))

GPIOPinWrite(GPIO_PORTF_BASE, GPIO_PIN_1, 0);

else

GPIOPinWrite(GPIO_PORTF_BASE, GPIO_PIN_1, 2);

}

//================================================================================================

void ADC0SS1IntHandler(void)

{

ADCIntClear(ADC0_BASE, 1);

ADCSequenceDataGet(ADC0_BASE, 1, ui32ADC0Value);

a = ui32ADC0Value[0];

b = ui32ADC0Value[1];

c = ui32ADC0Value[2];

d = ui32ADC0Value[3];

}

//==================================================================================================

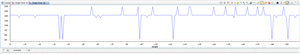

e.g. the graph of first value ui32ADC0Value[0] is shown

There are sudden random spikes, which correspond to readings of other channels.

If all 4 steps in the sequencer are configured to read the same channel then the issue does not arise. So hardware seems fine.

Has anyone encountered similar issue?

Thank you.

-Saurabh