Hi,

Is this viable to provide input to QEI from other input pulse source other than quadrature encoder?

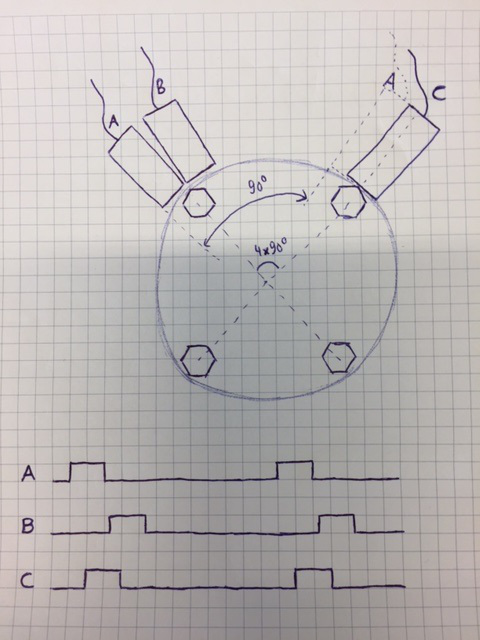

I want to use two different pulses (3.3V) coming out from two proximity sensors, placed adjacent to each other to detect 4 nuts on wheel.

Is this possible to give these sensors output (3.3V pulse) to QEI of TM4C123 micro-controller to sense number of pulses as well as the reverse direction of wheel?