Hello,

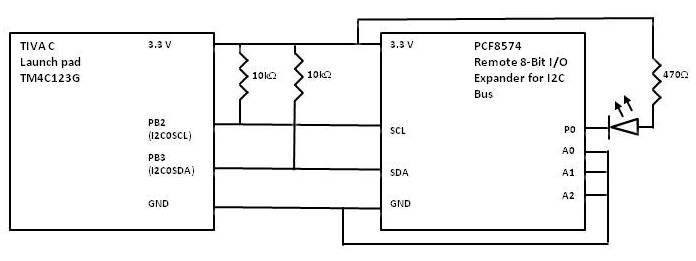

I am using TIVA C launch pad for my experiment. With reference to TIVA ware I2C example (loopback) mode I am configuring my application. Below is my schematic for the application.

SCL and SDA line continuously stay low. Please let me is there any corrections I need to do in hardware.

Below is my code. Reference is taken from Tiwaware example , I'm kind of stuck in it.

#include <stdbool.h>

#include <stdint.h>

#include "inc/hw_i2c.h"

#include "inc/hw_memmap.h"

#include "inc/hw_types.h"

#include "driverlib/gpio.h"

#include "driverlib/i2c.h"

#include "driverlib/pin_map.h"

#include "driverlib/sysctl.h"

#include "driverlib/uart.h"

#include "utils/uartstdio.h"

//*****************************************************************************

//

//! \addtogroup i2c_examples_list

//! <h1>I2C Master Loopback (i2c_master_slave_loopback)</h1>

//!

//! This example shows how to configure the I2C0 module for loopback mode.

//! This includes setting up the master and slave module. Loopback mode

//! internally connects the master and slave data and clock lines together.

//! The address of the slave module is set in order to read data from the

//! master. Then the data is checked to make sure the received data matches

//! the data that was transmitted. This example uses a polling method for

//! sending and receiving data.

//!

//! This example uses the following peripherals and I/O signals. You must

//! review these and change as needed for your own board:

//! - I2C0 peripheral

//! - GPIO Port B peripheral (for I2C0 pins)

//! - I2C0SCL - PB2

//! - I2C0SDA - PB3

//

// Number of I2C data packets to send.

//

//*****************************************************************************

#define NUM_I2C_DATA 3

//*****************************************************************************

//

// Set the address for slave module. This is a 7-bit address sent in the

// following format:

// [A6:A5:A4:A3:A2:A1:A0:RS]

//

// A zero in the "RS" position of the first byte means that the master

// transmits (sends) data to the selected slave, and a one in this position

// means that the master receives data from the slave.

//

//*****************************************************************************

#define SLAVE_ADDRESS 0x40

int

main(void)

{

//

// Set the clocking to run directly from the external crystal/oscillator.

// TODO: The SYSCTL_XTAL_ value must be changed to match the value of the

// crystal on your board.

//

SysCtlClockSet(SYSCTL_SYSDIV_1 | SYSCTL_USE_OSC | SYSCTL_OSC_MAIN |

SYSCTL_XTAL_16MHZ);

//

// The I2C0 peripheral must be enabled before use.

//

SysCtlPeripheralEnable(SYSCTL_PERIPH_I2C0);

//

// For this example I2C0 is used with PortB[3:2]. The actual port and

// pins used may be different on your part, consult the data sheet for

// more information. GPIO port B needs to be enabled so these pins can

// be used.

// TODO: change this to whichever GPIO port you are using.

//

SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOB);

//

// Configure the pin muxing for I2C0 functions on port B2 and B3.

// This step is not necessary if your part does not support pin muxing.

// TODO: change this to select the port/pin you are using.

//

GPIOPinConfigure(GPIO_PB2_I2C0SCL);

GPIOPinConfigure(GPIO_PB3_I2C0SDA);

//

// Select the I2C function for these pins. This function will also

// configure the GPIO pins pins for I2C operation, setting them to

// open-drain operation with weak pull-ups. Consult the data sheet

// to see which functions are allocated per pin.

// TODO: change this to select the port/pin you are using.

//

GPIOPinTypeI2CSCL(GPIO_PORTB_BASE, GPIO_PIN_2);

GPIOPinTypeI2C(GPIO_PORTB_BASE, GPIO_PIN_3);

//

// Enable loopback mode. Loopback mode is a built in feature that is

// useful for debugging I2C operations. It internally connects the I2C

// master and slave terminals, which effectively let's you send data as

// a master and receive data as a slave.

// NOTE: For external I2C operation you will need to use external pullups

// that are stronger than the internal pullups. Refer to the datasheet for

// more information.

//

HWREG(I2C0_BASE + I2C_O_MCR) |= 0x00;

//

// Enable and initialize the I2C0 master module. Use the system clock for

// the I2C0 module. The last parameter sets the I2C data transfer rate.

// If false the data rate is set to 100kbps and if true the data rate will

// be set to 400kbps. For this example we will use a data rate of 100kbps.

//

I2CMasterInitExpClk(I2C0_BASE, SysCtlClockGet(), false);

// Tell the master module what address it will place on the bus when

// communicating with the slave. Set the address to SLAVE_ADDRESS

// (as set in the slave module). The receive parameter is set to false

// which indicates the I2C Master is initiating a writes to the slave. If

// true, that would indicate that the I2C Master is initiating reads from

// the slave.

//

I2CMasterSlaveAddrSet(I2C0_BASE, SLAVE_ADDRESS, false);

// Place the data to be sent in the data register

//

I2CMasterDataPut(I2C0_BASE,0x00);

//

// Initiate send of data from the master. Since the loopback

// mode is enabled, the master and slave units are connected

// allowing us to receive the same data that we sent out.

//

I2CMasterControl(I2C0_BASE, I2C_MASTER_CMD_SINGLE_SEND);

// Wait until master module is done transferring.

//

while(I2CMasterBusy(I2C0_BASE))

{

}

while(1)

{

}

}