Hello,

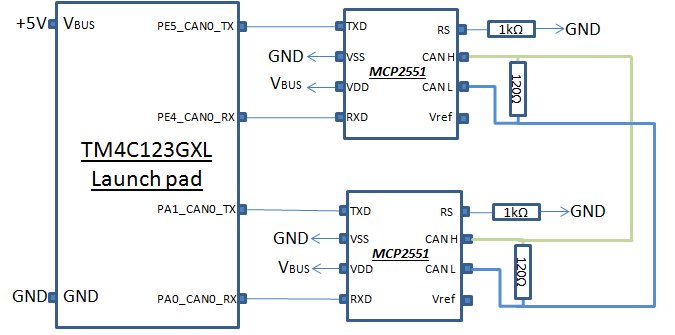

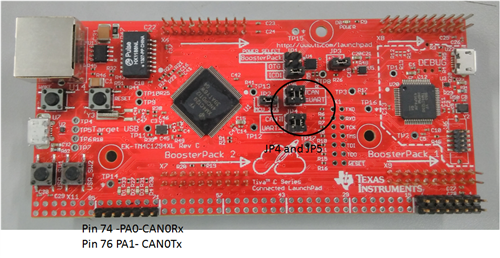

I want to learn about CAN communication. I am using TIVA TM4C123GXL Launchpad. After reading some previous posts about CAN I got the idea that I need two TIVA C boards for ideal CAN configuration. Since I don't have another one, is it possible to develop the communication on a single port but between two ports. As shown in below drawing:

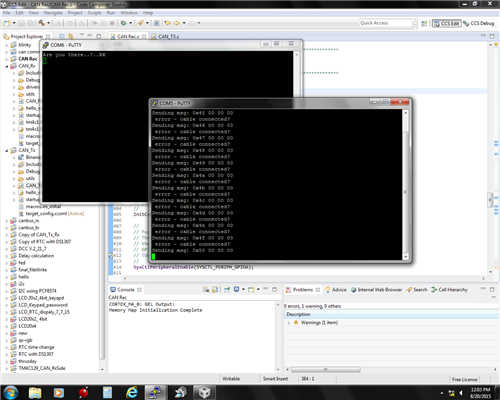

Another doubt is can I use the Simple_Rx and Simple_Tx code on the same controller. I have got sample transceiver IC SN65HVD1050D , will it work instead of MCP2551.

Please let me know is it a workable thing or not..?

Thank you.