Other Parts Discussed in Thread: TM4C123GH6PM, MOTORWARE, DRV8305, LM3S8971

I'm working on my Senior Project. It is a Brushless Gimbal System, like this one in youtube:

Brushless Gimbal examples: https://www.youtube.com/watch?v=qOuMNiSc8Qw

Actually, the big challenge is just to do a rotor positioning control of a brushless DC motor where the orientation angle is measured by a IMU sensor. The motor I am using is the EMAX CF2822. Here is a video of someone driving one CF2822:

EMAX CF 2822 - Position Control of a Brushless DC motor https://www.youtube.com/watch?v=tAXfprfT-rE

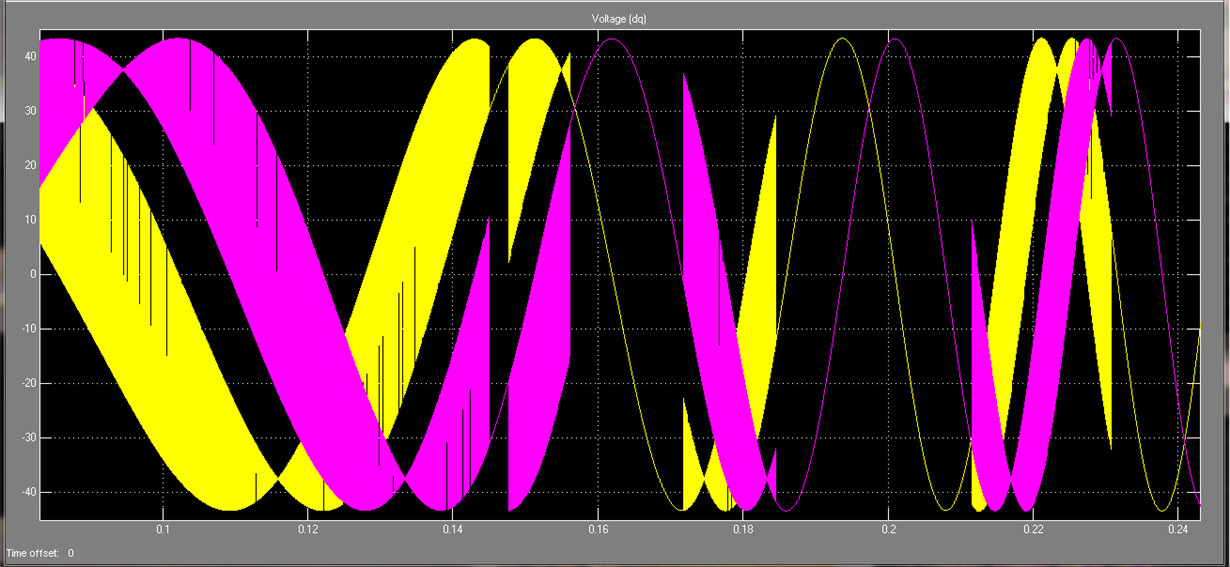

I have been working in this project for about 6 months. Now I have the motor driver (I.C. L6234) connected to the EMAX 2822, but I'm having such a big difficult to figure out how to generate 3 PWM outputs shifted by 120 degrees so then I can drive the brushless motor using the Tiva C board - TM4C123GH6PM microcontroller.

Could you help me with this issue? I have been reading the large TM4C123GH6PM datasheet, but I couldn't make the code work until now.

Best Regards,

Feliphe