Hello everyone.

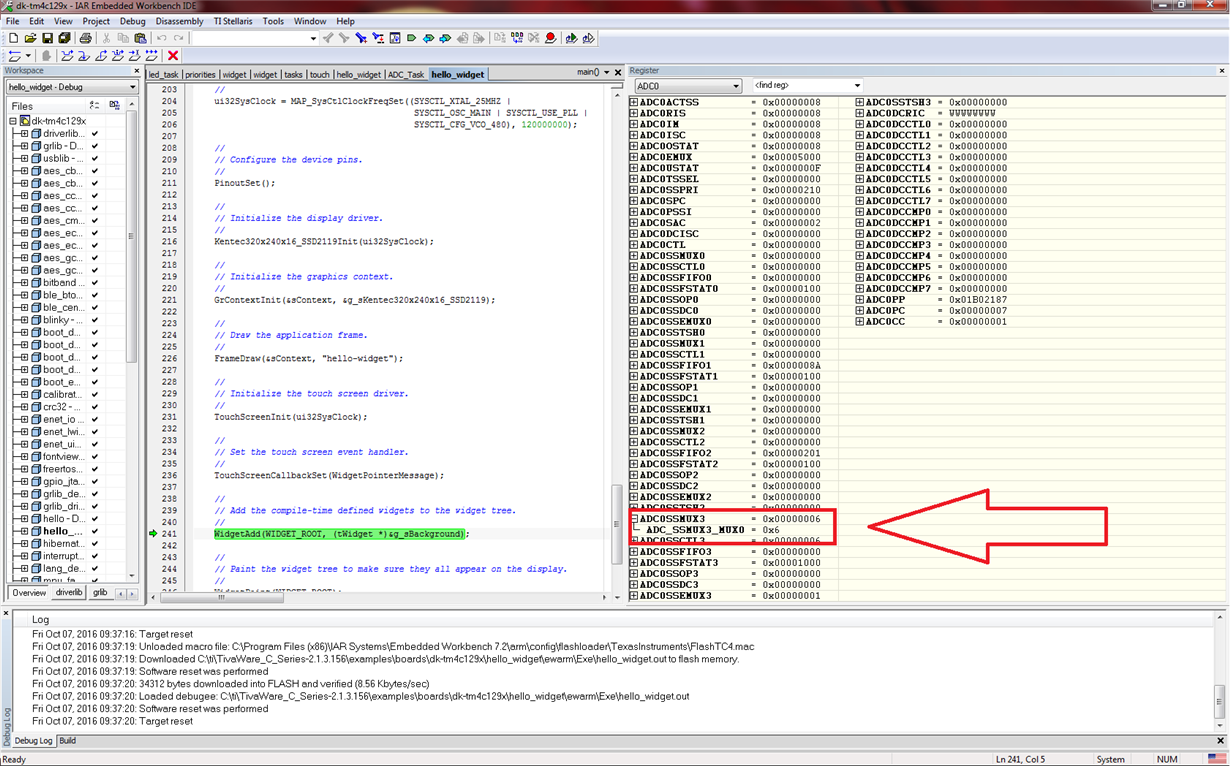

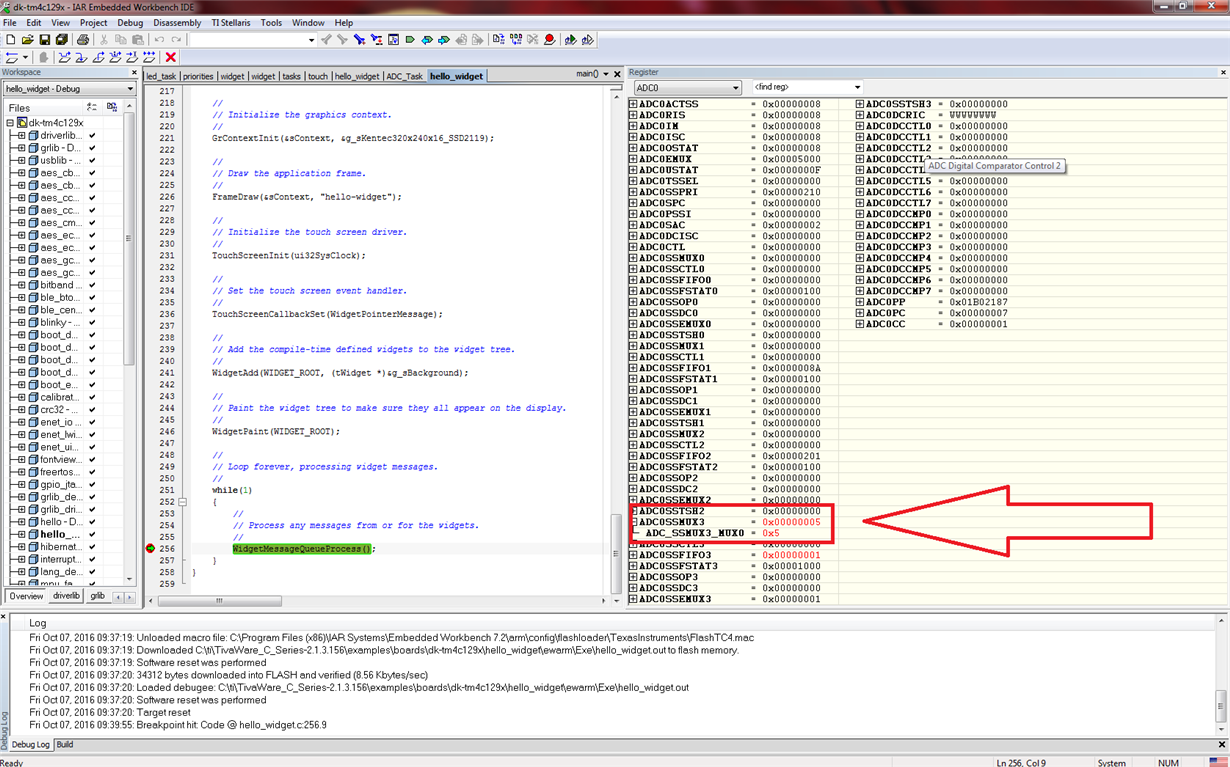

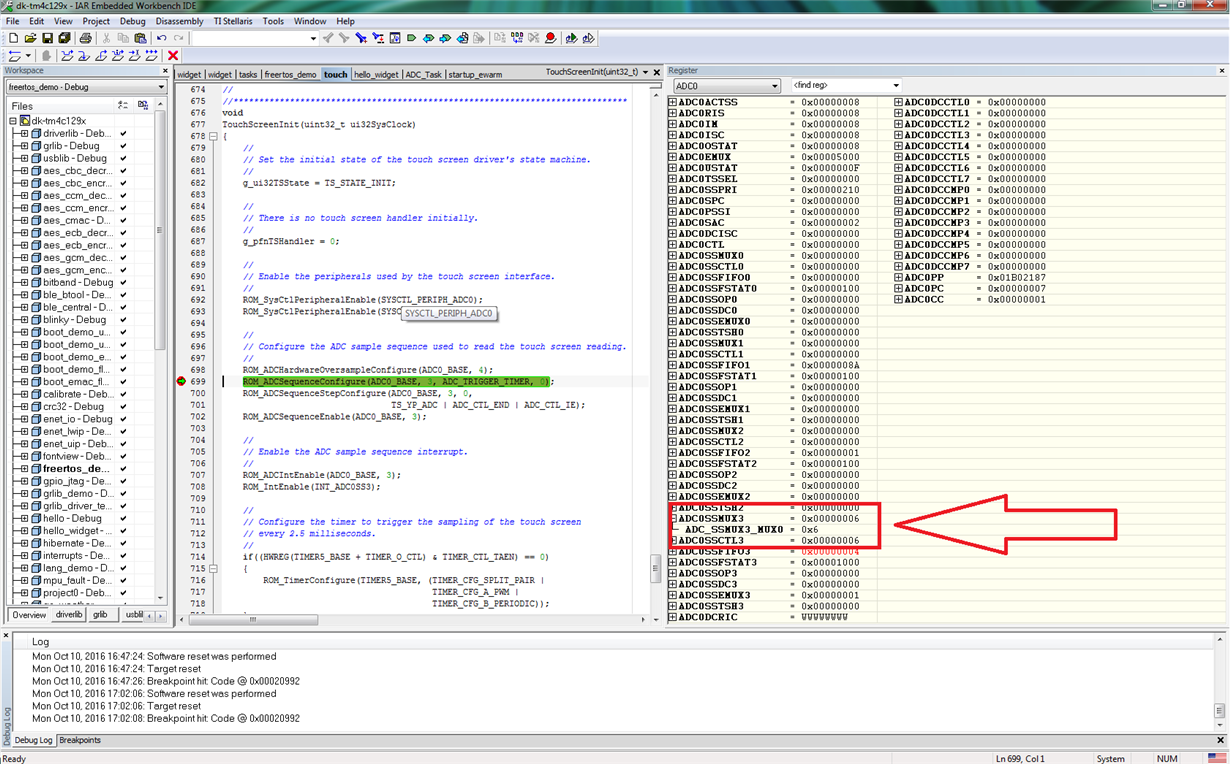

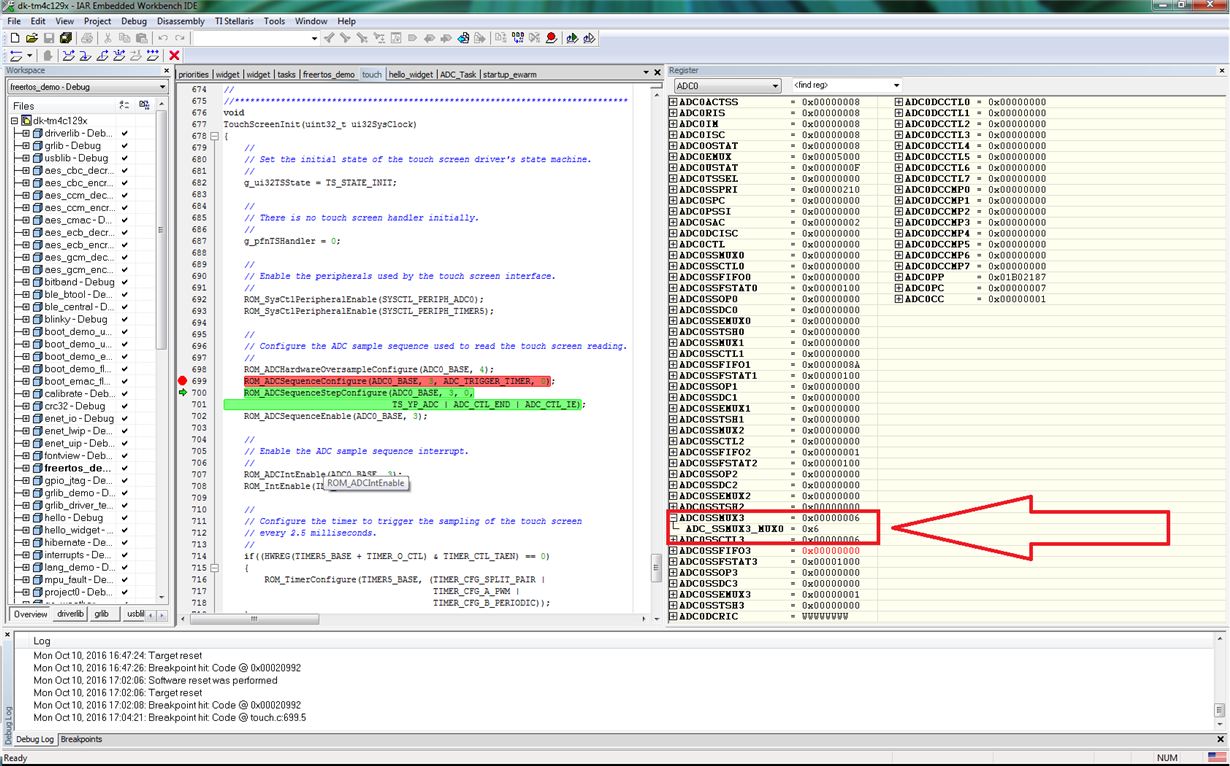

I'm new using the TM4C129x, for the moment I want to read values from two ADC channels with the ADC1 (because I see that ADC0 is used by the touchscreen) and at the same time use the touchscreen, everything working in FreeRTOS.

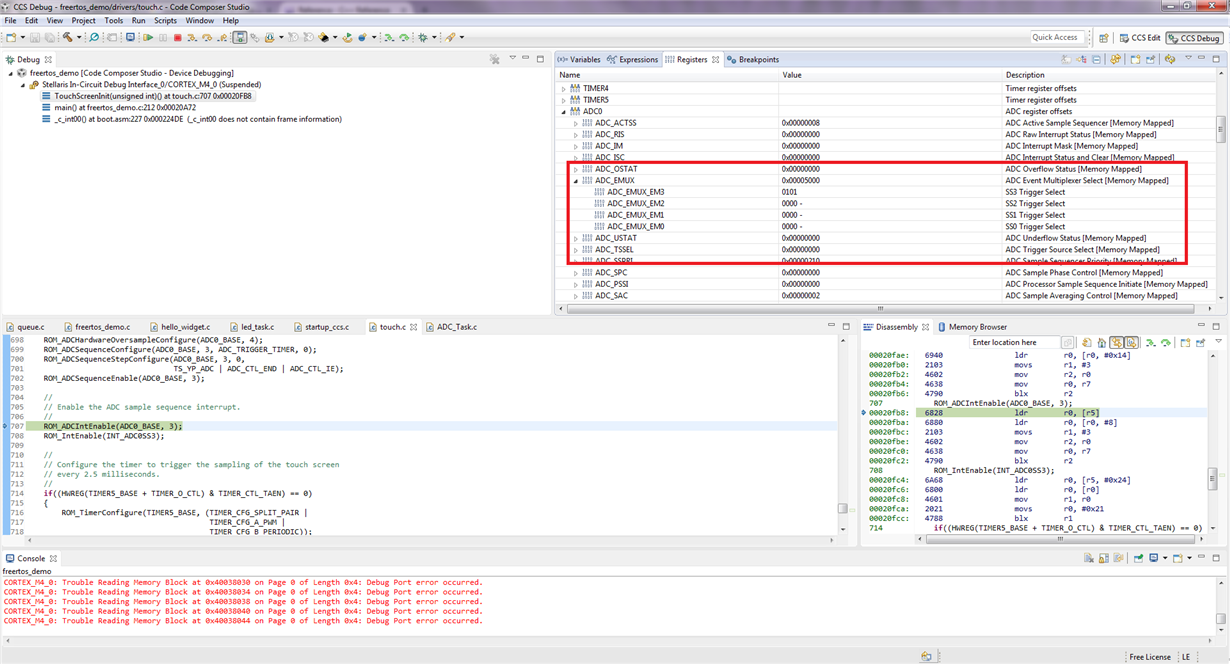

The problem is that when I try to put them to work together the touch doesn't work, I have a task to control the ADC and another for the LCD, both tasks have the same priority.

I have check the individual codes running alone and both works but when I try to put them together it fails the touch. Below I leave you what I think is the important code

First the ADC configuration:

void

InitADC(void)

{

//

// Habilita el módulo del ADC1

//

ROM_SysCtlPeripheralDisable(SYSCTL_PERIPH_ADC1);

ROM_SysCtlPeripheralReset(SYSCTL_PERIPH_ADC1);

ROM_SysCtlPeripheralEnable(SYSCTL_PERIPH_ADC1);

while(!(ROM_SysCtlPeripheralReady(SYSCTL_PERIPH_ADC1)));

//

// Habilita el puerto E (Ahí están los canales del ADC que vamos a usar)

//

ROM_SysCtlPeripheralDisable(SYSCTL_PERIPH_GPIOE);

ROM_SysCtlPeripheralReset(SYSCTL_PERIPH_GPIOE);

ROM_SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOE);

while(!(ROM_SysCtlPeripheralReady(SYSCTL_PERIPH_GPIOE)));

//******************************************************************************

//

// Start the ADC sequence configuration

//

//******************************************************************************

//

// Configura dos pines del puerto E (E1 y E2) como entradas del ADC

//

GPIOPinTypeADC(GPIO_PORTE_BASE, GPIO_PIN_3);

GPIOPinTypeADC(GPIO_PORTE_BASE, GPIO_PIN_2);

//

// Configura el ADC para trabajar a 16MHz (480MHz(reloj principal) entre 30(prescaler))

//

ADCClockConfigSet(ADC1_BASE, ADC_CLOCK_SRC_PLL | ADC_CLOCK_RATE_FULL, 30);

//

// Configura el secuenciador 0 del ADC1 para que sea disparado por software

// con prioridad 0

//

ROM_ADCSequenceConfigure(ADC1_BASE, 0, ADC_TRIGGER_PROCESSOR, 0);

//

// Configura los steps del secuenciador 0 para tomar una muestra del canal 0

// y después una muestra del canal 1, esta última muestra dispara la

// interrupción del ADC y finaliza la secuencia.

//

ROM_ADCSequenceStepConfigure(ADC1_BASE, 0, 0, ADC_CTL_CH0);

ROM_ADCSequenceStepConfigure(ADC1_BASE, 0, 1, ADC_CTL_CH1 | ADC_CTL_IE | ADC_CTL_END);

//

// Limpia la interrupción del ADC antes de habilitarla para evitar falsos

// disparos.

//

ADCIntClearEx(ADC1_BASE, ADC_INT_SS0);

ROM_ADCIntEnableEx(ADC1_BASE, ADC_INT_SS0);

//

// Habilitamos el secuenciador 0 para que comience el muestreo

//

ROM_ADCSequenceEnable(ADC1_BASE, 0);

//******************************************************************************

//

// Finish the ADC sequence configuration

//

//******************************************************************************

//

// Se habilita la interrupción del ADC

//

ROM_IntEnable(INT_ADC1SS0);

}

ADC interrupt handler:

void

ADC1SS0IntHandler(void)

{

uint32_t samples[NUM_SAMPLES];

int iRetVal = 0;

//

// Clear any pending status

//

ADCIntClearEx(ADC1_BASE, ADC_INT_SS0);

//

// Lee el valor obtenido por el ADC

//

iRetVal = ADCSequenceDataGet(ADC1_BASE, 0, samples);

if(iRetVal == 2)

{

//Some calculations

}

}

ADC Task:

void

ADCTask(void *pvParameters)

{

//

// Habilita el reloj para el TIMER0

//

ROM_SysCtlPeripheralEnable(SYSCTL_PERIPH_TIMER0);

//

// Habilita interrupciones del procesador

//

ROM_IntMasterEnable();

//

// Configura el submodulo TIMER_A del modulo TIMER0

//

ROM_TimerConfigure(TIMER0_BASE, TIMER_CFG_PERIODIC);

ROM_TimerLoadSet(TIMER0_BASE, TIMER_A, 120000);

//

// Setup the interrupts for the timer timeouts.

//

ROM_IntEnable(INT_TIMER0A);

ROM_TimerIntEnable(TIMER0_BASE, TIMER_TIMA_TIMEOUT);

//

// Habilita los timers

//

ROM_TimerEnable(TIMER0_BASE, TIMER_A);

InitADC();

while(1)

{

if(DoOperations)

{

DoOperations = false;

TOCOandBPMCalculation();

}

}

}

Display Task

void

WidgetTask(void *pvParameters)

{

//

// Add the compile-time defined widgets to the widget tree.

//

GetScreen(1,&Imagen_a_mostrar);

WidgetAdd((tWidget*)&g_sBackground, (tWidget*)Imagen_a_mostrar);

WidgetAdd(WIDGET_ROOT,(tWidget*)&g_sBackground);

//

// Paint the widget tree to make sure they all appear on the display.

//

WidgetPaint(WIDGET_ROOT);

//

// Loop forever, processing widget messages.

//

while(1)

{

//

// Process any messages from or for the widgets.

//

WidgetMessageQueueProcess();

}

}

Sorry for the code in Spanglish, I hope you can help me and feel free to ask for more parts of the code and I'm using IAR by the way.

Regards, Juan