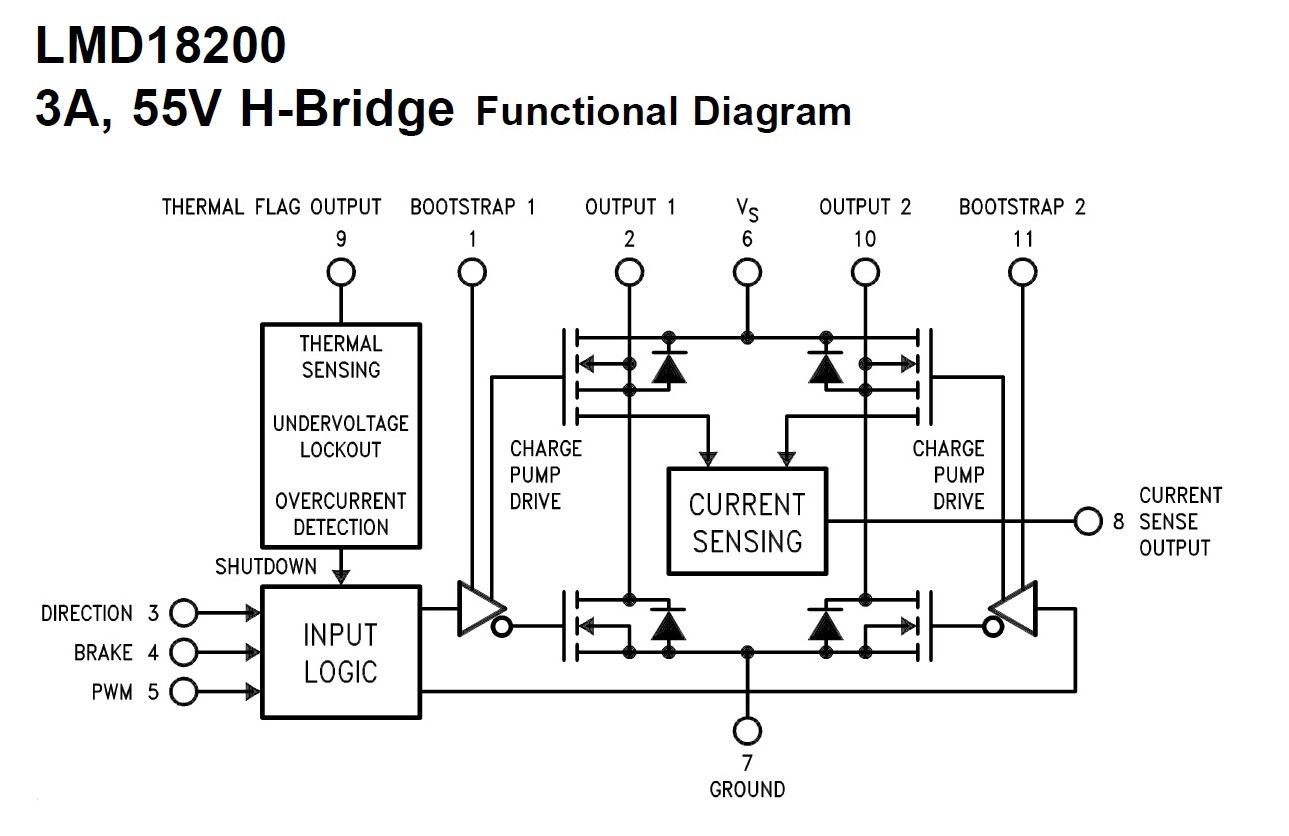

Other Parts Discussed in Thread: ENERGIA, LMD18200, TM4C123GH6PM

I am using a TM4C123GXL and H-Bridge for DC motor control. I managed to generate a PWM signal and control the speed of the motor, but only in 1 direction. I cannot get to reverse the direction of the motor. The H-Bridge logic inputs need to be inverted to reverse the direction. However, I cannot seem to do that with code. On Arduino, people have been using digitalWrite( (Pin Number), LOW) and digitalWrite( (Pin Number), HIGH) and have worked for them. Is there any way to do that but in a Code Composer Studio project? I am not trying to use Energia.

I know for high, GPIOPinWrite() works but I can't seem to get the low part.

Any help would be greatly appreciated!!!