Target

Tiva TM4C1294NCPDT Launchpad (EK-TM4C1294XL)

Note - XTAL (Y1) is 25MHz

Problem

The code below is designed to generate a 25 kHz PWM signal (T=40us) but is observed with a period of 31.1us.

Code & Scope Capture

int main(void) {

//Clock Init

SysCtlClockFreqSet((SYSCTL_XTAL_25MHZ | SYSCTL_OSC_MAIN | SYSCTL_USE_OSC), 25000000); /* 25MHz external XTAL (Y1) */

//******************************************************************************************************************************//

// GPIO MODULE INIT //

//******************************************************************************************************************************//

SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOF); /* enable GPIO Port F */

GPIOPinConfigure(GPIO_PF2_M0PWM2); /* set pin-muxes */

GPIOPinConfigure(GPIO_PF3_M0PWM3);

GPIOPinTypePWM(GPIO_PORTF_BASE, GPIO_PIN_2); /* set gpio-modules to push-pull output */

GPIOPinTypePWM(GPIO_PORTF_BASE, GPIO_PIN_3);

//******************************************************************************************************************************//

// PWM MODULE INIT //

//******************************************************************************************************************************//

//Init PWM Module

SysCtlPeripheralEnable(SYSCTL_PERIPH_PWM0); /* Enable the PWM0 peripheral */

while(!SysCtlPeripheralReady(SYSCTL_PERIPH_PWM0)); /* Wait for the PWM0 module to be ready */

PWMGenConfigure(PWM0_BASE, PWM_GEN_1, /* Configure the PWM generator for count down with */

PWM_GEN_MODE_DOWN | PWM_GEN_MODE_NO_SYNC); /* with immediate updates to the parameters */

//Init PWM0 Gen1

PWMGenPeriodSet(PWM0_BASE, PWM_GEN_1, 500); /* 100% (40us) Tpwm_clk=80ns, 80n*500 = 40us (25kHz) */

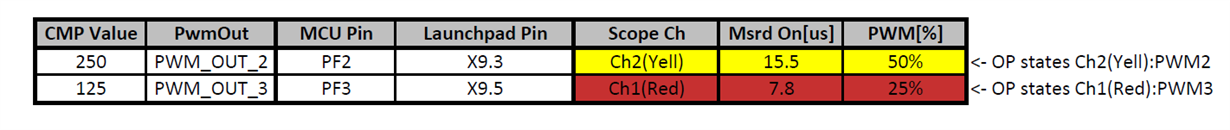

PWMPulseWidthSet(PWM0_BASE, PWM_OUT_2, 250); /* 50% (20us) */

PWMPulseWidthSet(PWM0_BASE, PWM_OUT_3, 125); /* 25% (10us) */

//Start PWM Module

PWMGenEnable(PWM0_BASE, PWM_GEN_1); /* Start the timers in Generator Module 1 */

PWMOutputState(PWM0_BASE, (PWM_OUT_2_BIT | PWM_OUT_3_BIT), true); /* Enable the outputs */

//spin

for(;;) {

_nop();

}

}

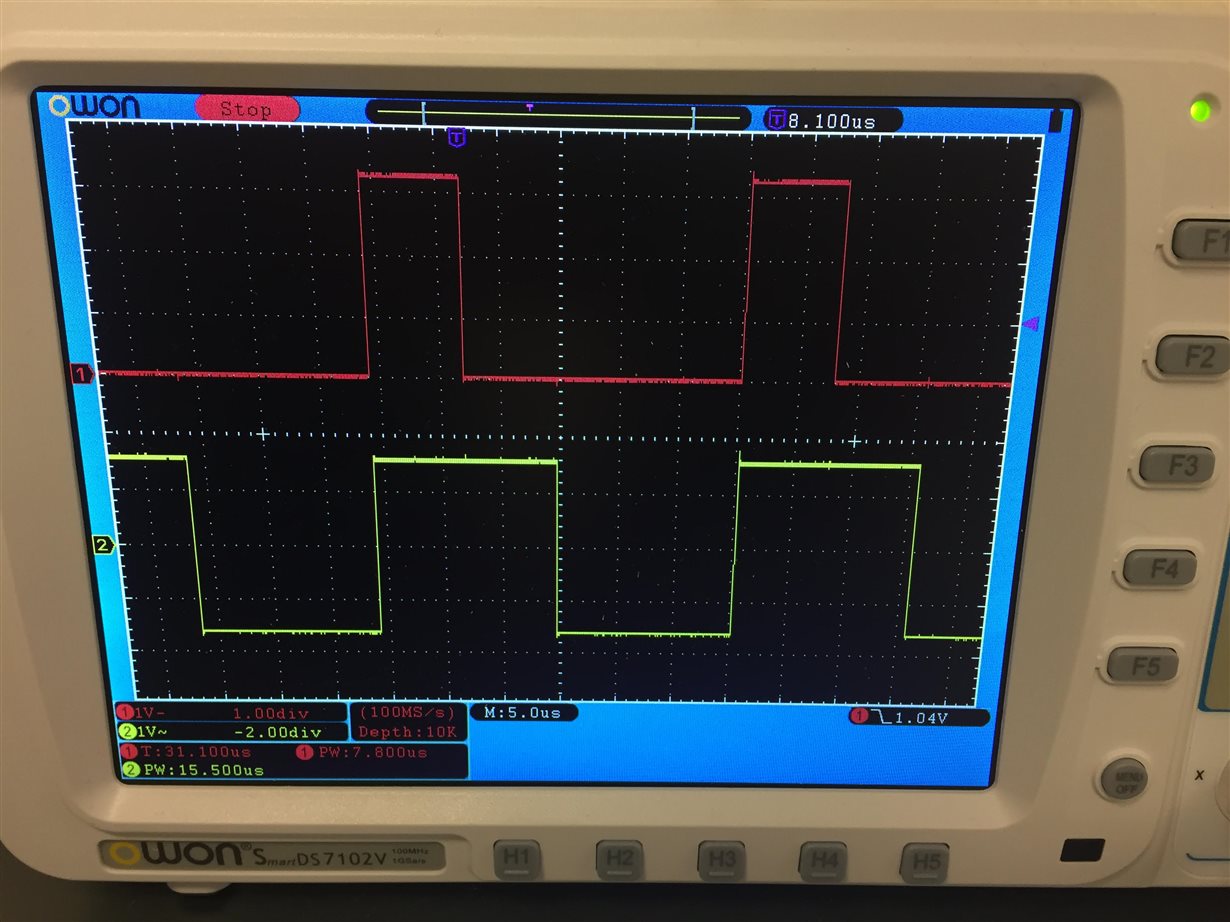

See below for measured results, Ch1(Red): PWM3, Ch2(Yellow): PWM2 -

Question

Why do I see a period of 31us, not 40us?

Calculations Used

Fclk = 25MHz, Fclk_pwm = 12.5 MHz

Tclk_pwm = 80ns

N_per_pwm = 500

T_per_pwm = 40us (but 31.1us observed?)