I am using TM4C123GH6PM lauchpad.

IAR developement software.

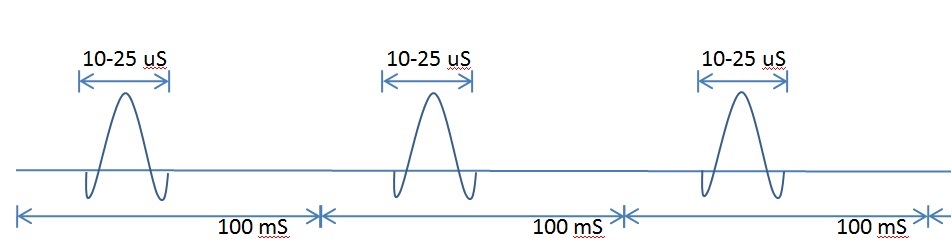

I wanted to use two sensor on A0 & A1 pins.

Read the values sequencially, do the processing.

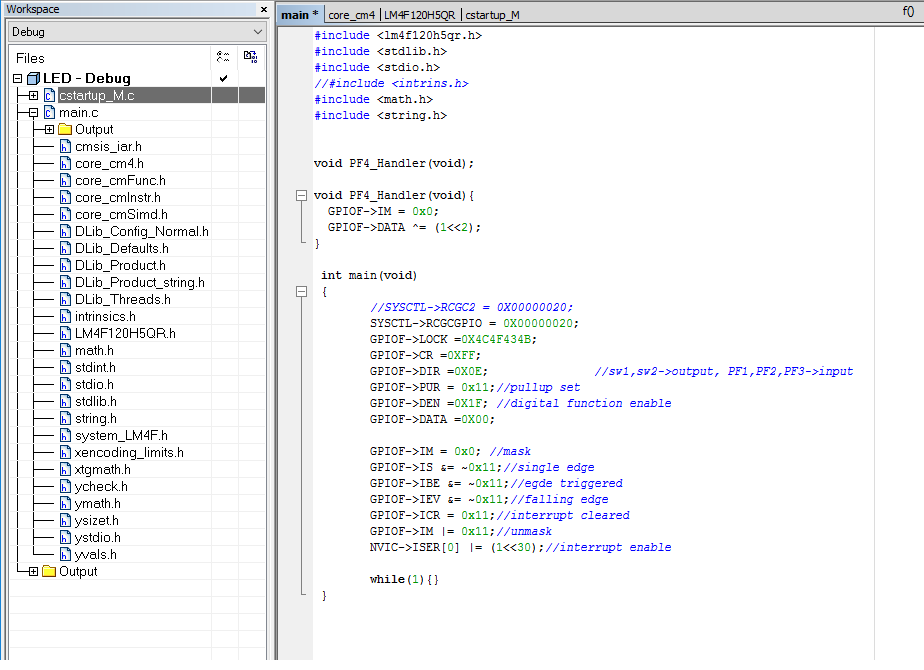

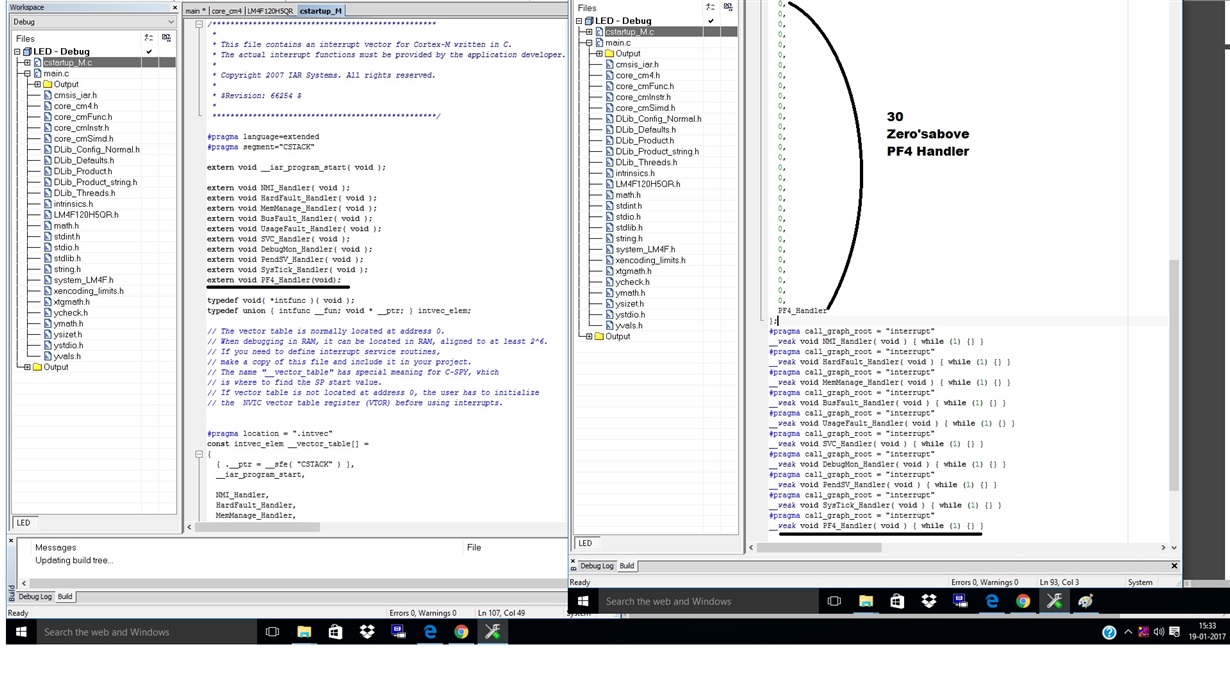

Here is my code.

Please correct:

......................................................................................................................................................................................................................................

#include <lm4f120h5qr.h>

#include <stdlib.h>

#include <stdio.h>

//#include <intrins.h>

#include <math.h>

#include <string.h>

/* ...........................................

DATA PA4 13

SCK PA2 11

SS PA3 12

............................................*/

unsigned long ADC_RESULT=0;

float ADC_RESULT1=0;

void adc_init();

unsigned long ADC();

void send_dac();

void serial_clk();

unsigned long ADC()

{

unsigned long result;

ADC0->PSSI = 0X0004; //Begin sampling on Sample Sequencer 2

while((ADC0->RIS &0X04)==0);

result = ADC0->SSFIFO2 &0XFFF;

ADC0->ISC = 0X0004;

return result;

}

int main(void)

{

//...13.4.1 Module Initialization pg. 817

SYSCTL->RCGCADC =0X00000001; //1. ADC 0 module selected

//General purpose I/O Run Mode Clock RRCGCGPIO pg. 340

SYSCTL->RCGCGPIO=0X00000011; //2. Port A & Port E are selected

//DAC Pin settings

// GPIO direction GPIODIR pg. 663

GPIOA->DIR =0X1C; // PA2, PA3, PA4 as output pin

// GPIO Digital Enable (GPIODEN) pg.682

GPIOA->DEN =0X1C; // PA2, PA3, PA4 are Digital Enabled

// GPIO Data (GPIODATA) pg. 662

GPIOA->DATA =0X08; // Initial pin data

//ADC port pin initialization

GPIOE->AFSEL = (1<<2)|(1<<3); //3. Set the GPIOAFSELbits for the ADC input pins

GPIOE->DEN &= ~0X0C; //4. Configure theAINx signals to be analog inputs by clearing the correspondingDENbit in the GPIO Digital Enable (GPIODEN)

GPIOE->AMSEL = (1<<2)|(1<<3); //5. Disable the analog isolation circuit for all ADC input pins that are to be used by writing a 1 to the appropriate bits of the GPIOAMSELregister

GPIOE->DIR &= ~0X0C;

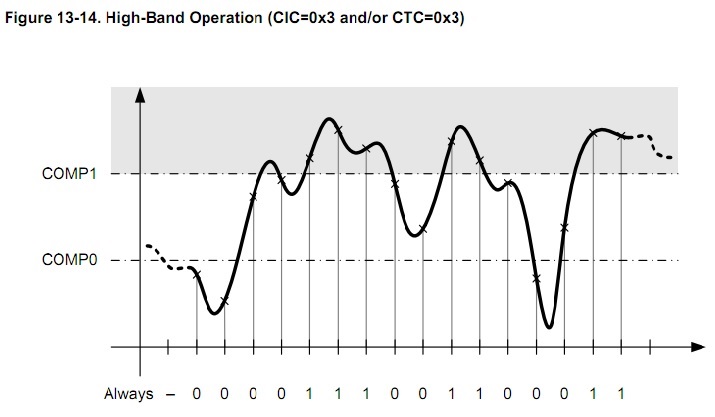

//13.4.2 Sample Sequencer Configuration

ADC0->ACTSS &= ~0X0004; //1. Ensure that the sample sequencer is disabled by clearing the correspondingASENnbit in the ADCACTSSregister

// ADC SS2 Enable- 4 sample

ADC0->EMUX = 0XF000; //2. Configure the trigger event for the sample sequencer in theADCEMUX register

// set as Continuously sample

ADC0->SSMUX3 = 1; //4. For each sample in the sample sequence, configure the corresponding input source in the ADCSSMUXnregister

ADC0->SSMUX2 = 0; // SSMUX3 -> AIN1 & SSMUX2 -> AIN0

ADC0->SSCTL2 = 0X60; //5. For each sample in the sample sequence, configure the sample control bits in the corresponding nibble in theADCSSCTLn register

// 2nd sample is last sample and Interrupt enabled after that (This for SS2)

ADC0->IM = (1<<2); //6. interrupts are to be used, set the corresponding MASKbit in the ADCIM

// ADCSSCTL2 IEn bit is set

ADC0->ACTSS |= 0X0004; //7. Enable the sample sequencer logic by setting the correspondingASENnbit in the ADCACTSS register

ADC0->SSPRI = 0X1023;

while(1)

{

ADC_RESULT = ADC();

ADC_RESULT1 = (ADC_RESULT/4095)*3.3;

ADC_RESULT = ADC_RESULT | 0x3000;

}

}.....................................................................................................................................................................................................................................

I dont understand ADC_RESULT will have which value, from AIN0 or AIN1.

and how to get both value from AIN0 or AIN1.