I have a board with 4 small dc motors connected to H-Bridges and 1 hobby-style servo connected. I was running a script for a few hours to stress test the board. I heard my PC complaining about the USB dropping out, so I checked on it and the CPU was hot to the touch. After turning off the equipment and coming back later, the CPU does heat up quickly once power is applied.

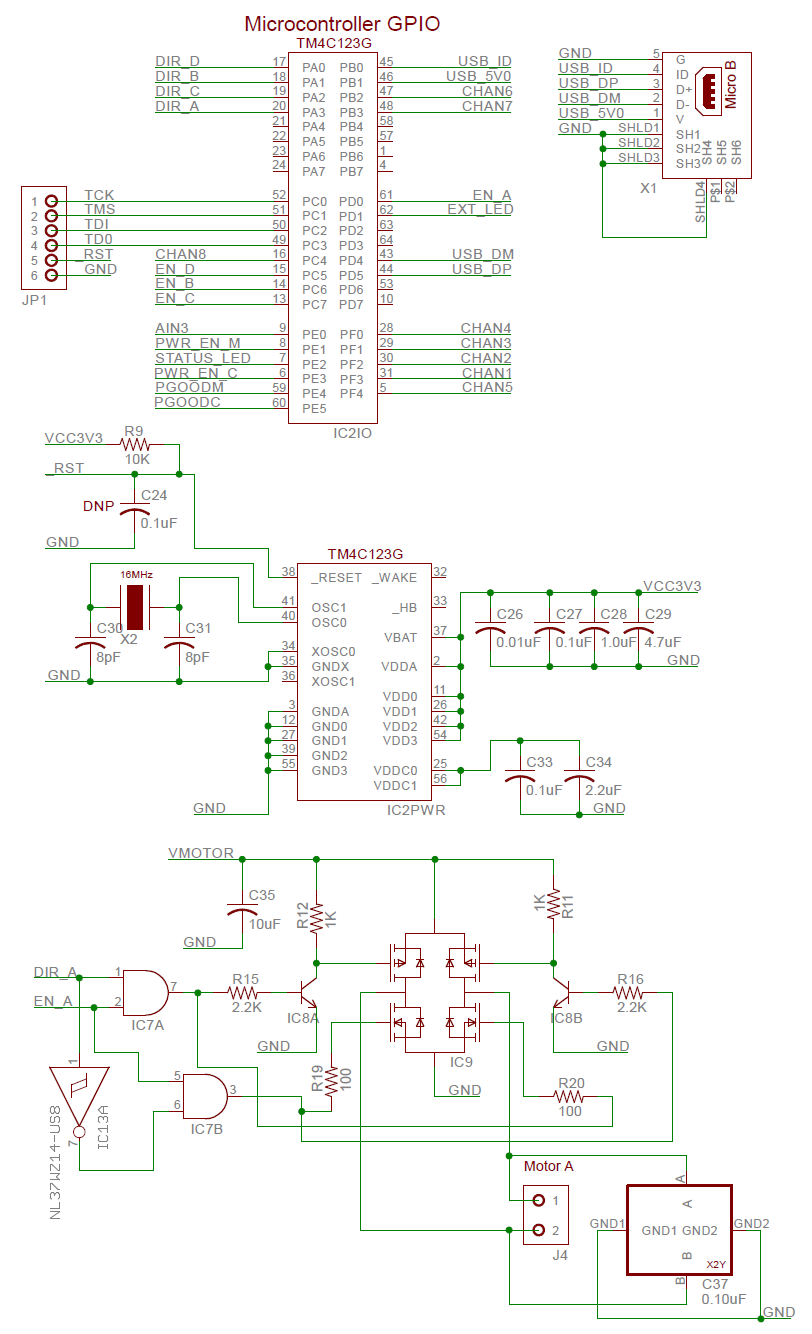

The board draws between 7 and 10mA more than it did previously during idle, however everything appears to function correctly - albiet at a high temperature. I believe this indicates transistor level damage to the chip itself, however I do not know where I need to add protection or rework the board.

Also, I was wondering if it might be due to my neglecting the addition of resistors between GPIO pins and the h-bridge components. However, it is my understanding that there are current limiting components in the GPIO peripheral pins which would make this concern a non-issue.

Please help out with advice - this board is for a robotics platform used for getting kids interested in writing software and developing hardware.