Part Number: TM4C129ENCPDT

Other Parts Discussed in Thread: SEGGER, TM4C1294NCPDT

Tool/software: Code Composer Studio

I have the kit "Tiva C Series TM4C1294 Connected LaunchPad" which is used to program our new board containing TM4C129ENCPDT, but when trying to program the MCU it is showing as "Error connecting to the target". When we try to program our old board its working fine with same code.

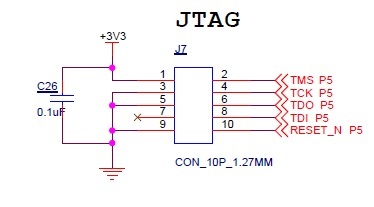

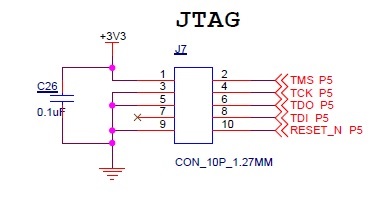

Am also attaching old and new design here.

Error

Old Design (programmable)

What seems to be the problem here?

Regards,

Muhsin Ali