Other Parts Discussed in Thread: ULN2003A

Hi Champs,

My customer is designing control board using TM4C1294. And recently they found MCU would jump to hardfault_handler when operating solenoid valve.

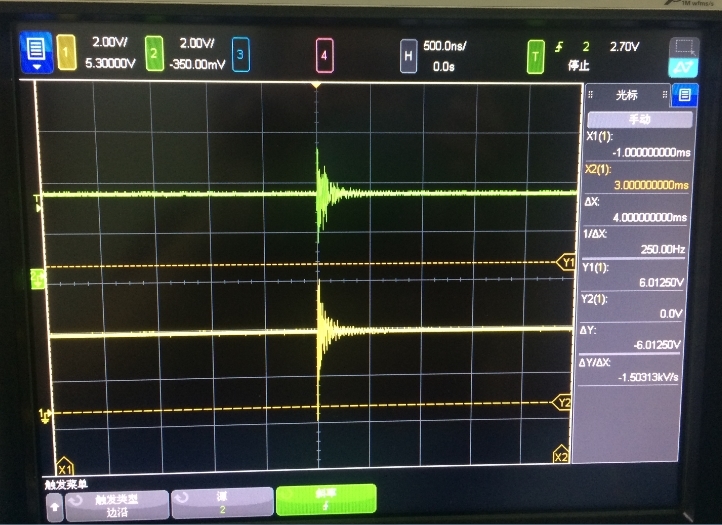

Then we measured the VDD using scope, and found there were some glitch on VDD when operating valve. And reset from RST pin and debugger can recover. And if absorption circuit was added on relay and valve, the probability would be decrease significantly. But still cannot guarantee the issue was solved.

Would you kindly suggest what should we do? I can share the schematics and PCB to you offline.

Thanks.

BR,

Young