Tool/software: Code Composer Studio

Hi,

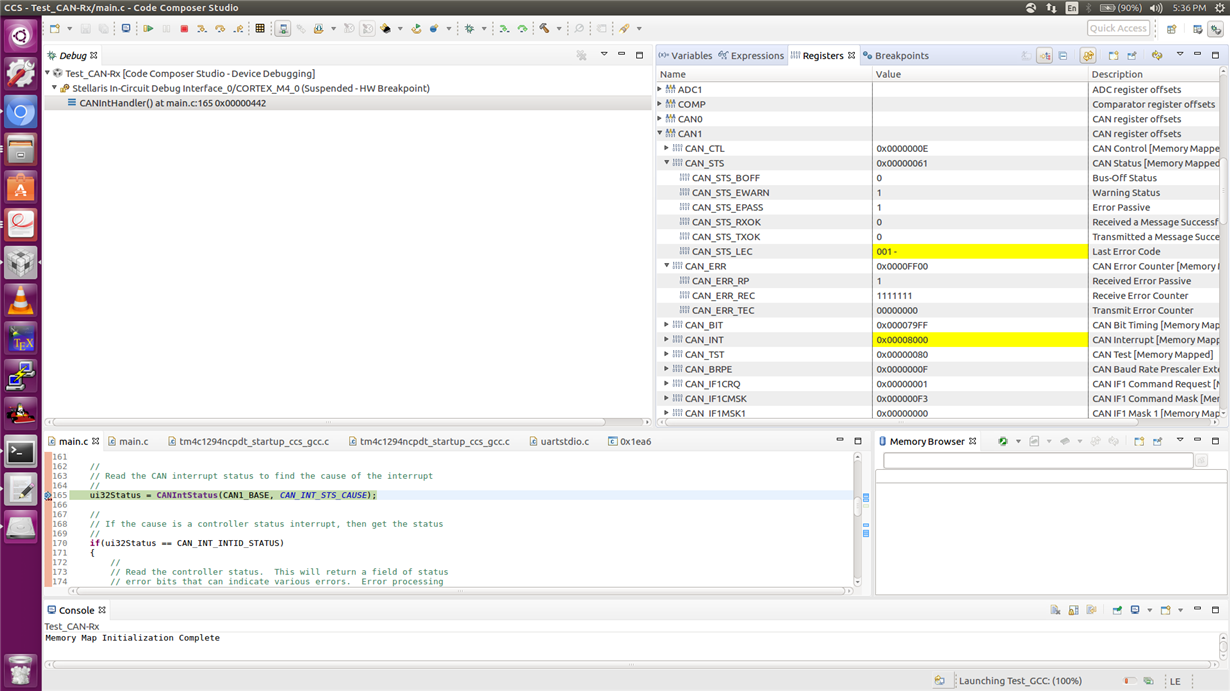

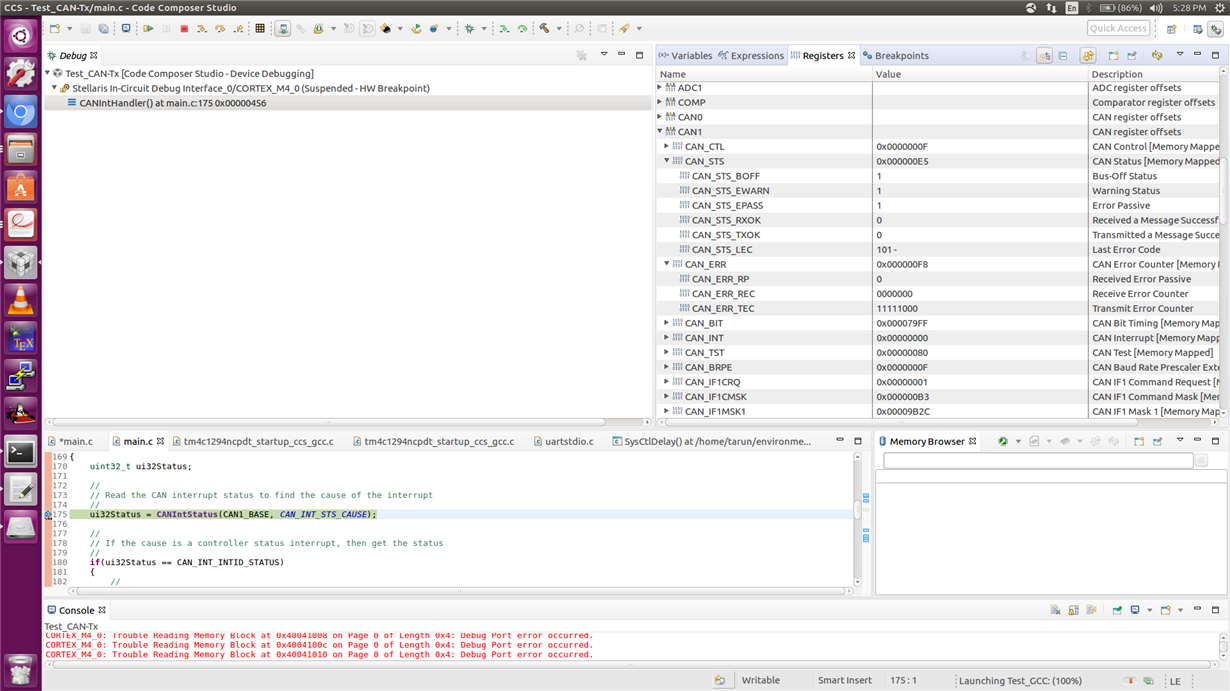

I am attempting to use the CAN bus on my TM4C1294XL. I started with the simple Rx and Tx codes and changed it to use the CAN1 so that I could use the UART0 for monitoring data. I am using two MCP2551 as the transceivers with 120 ohm termination resistors with RS terminal grounded. When I attempt to transmit, I get an errors in both the controllers. I have attached the register description of both Transmit and receive. The Rx interrupt occurs only when I connect the Tx m/c. As I understand, the Tx and Rx error counters have filled which causes the error. So i tried reducing the transmission rate to 100 Kbps, I have also tried the multiple Tx and multiple Rx and the results are the same. Please let me know what could be the issue. The files are attached for reference along with the register description of the m/c.