Other Parts Discussed in Thread: SN74HCT245, SN74LVC4245A, EK-TM4C1294XL

Hi

Two programs are now designed:

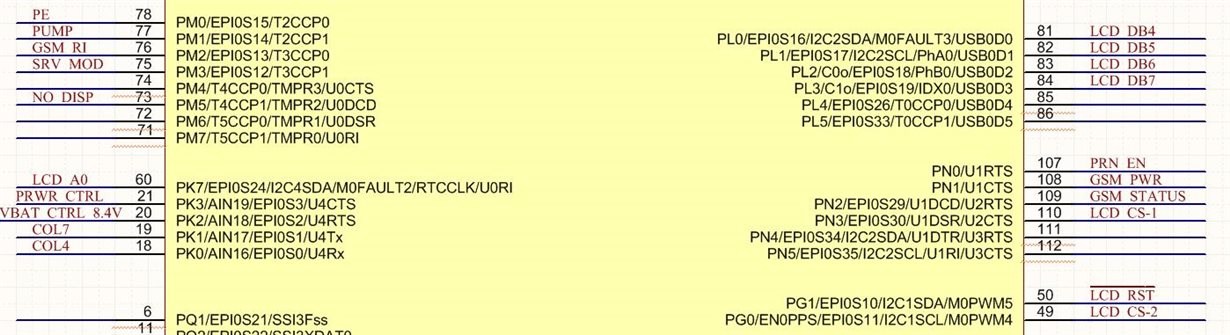

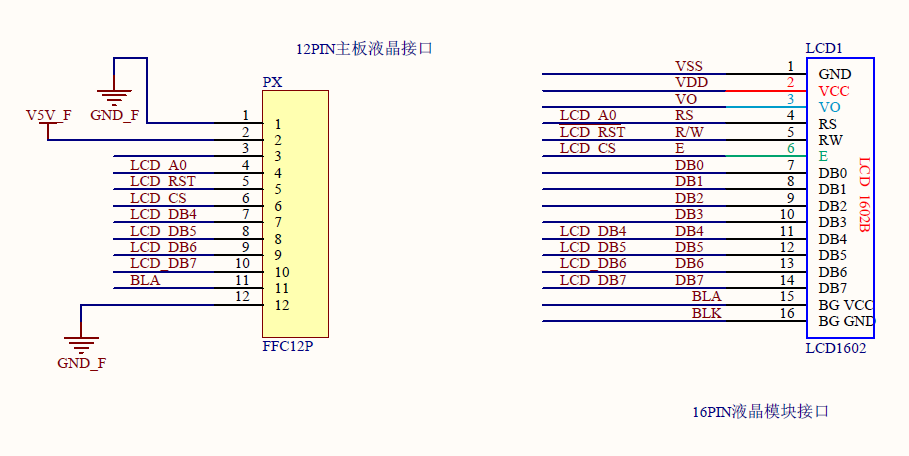

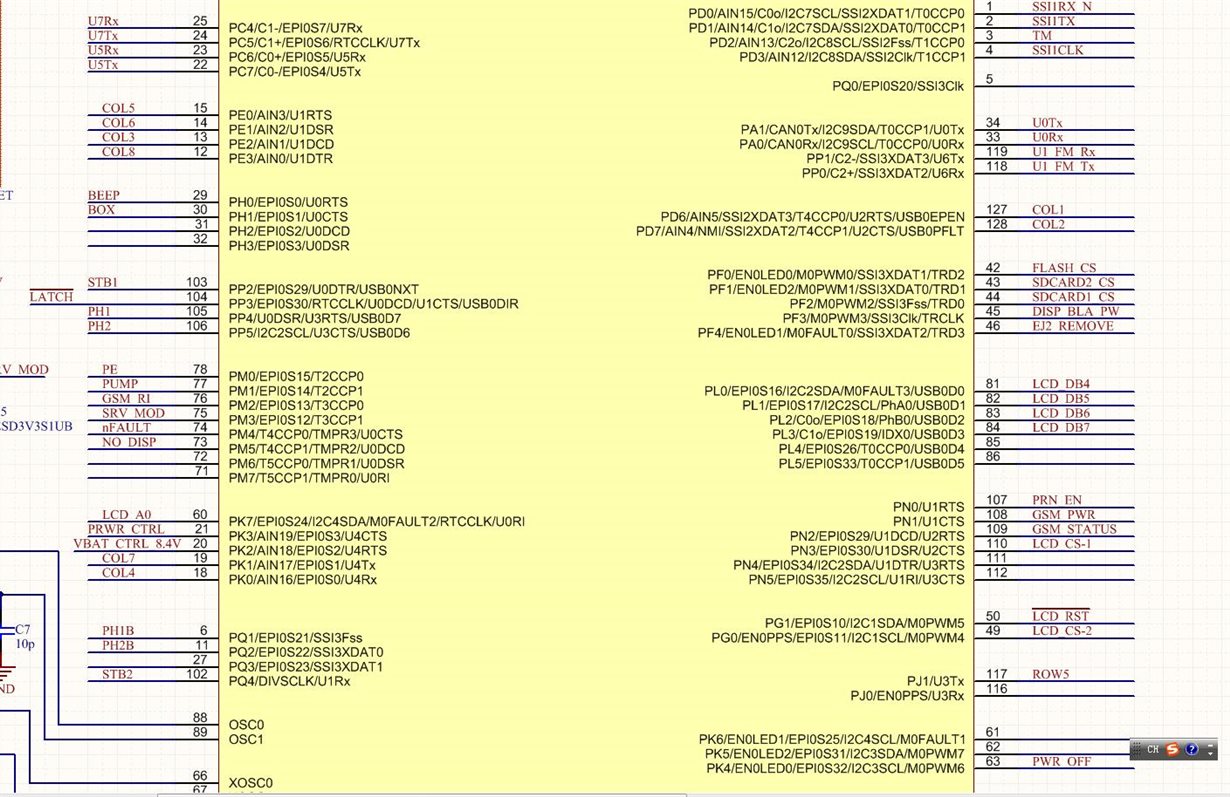

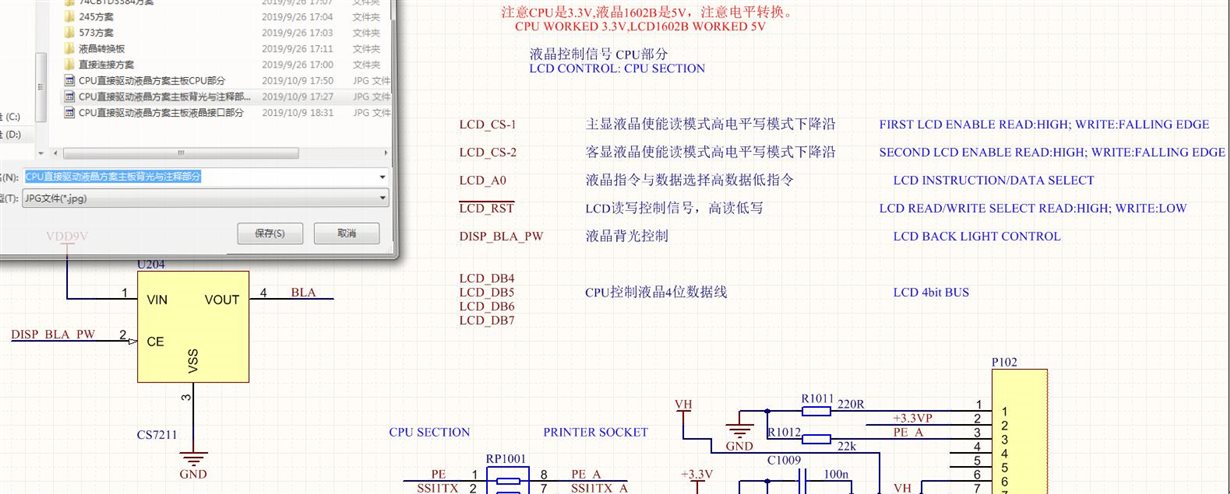

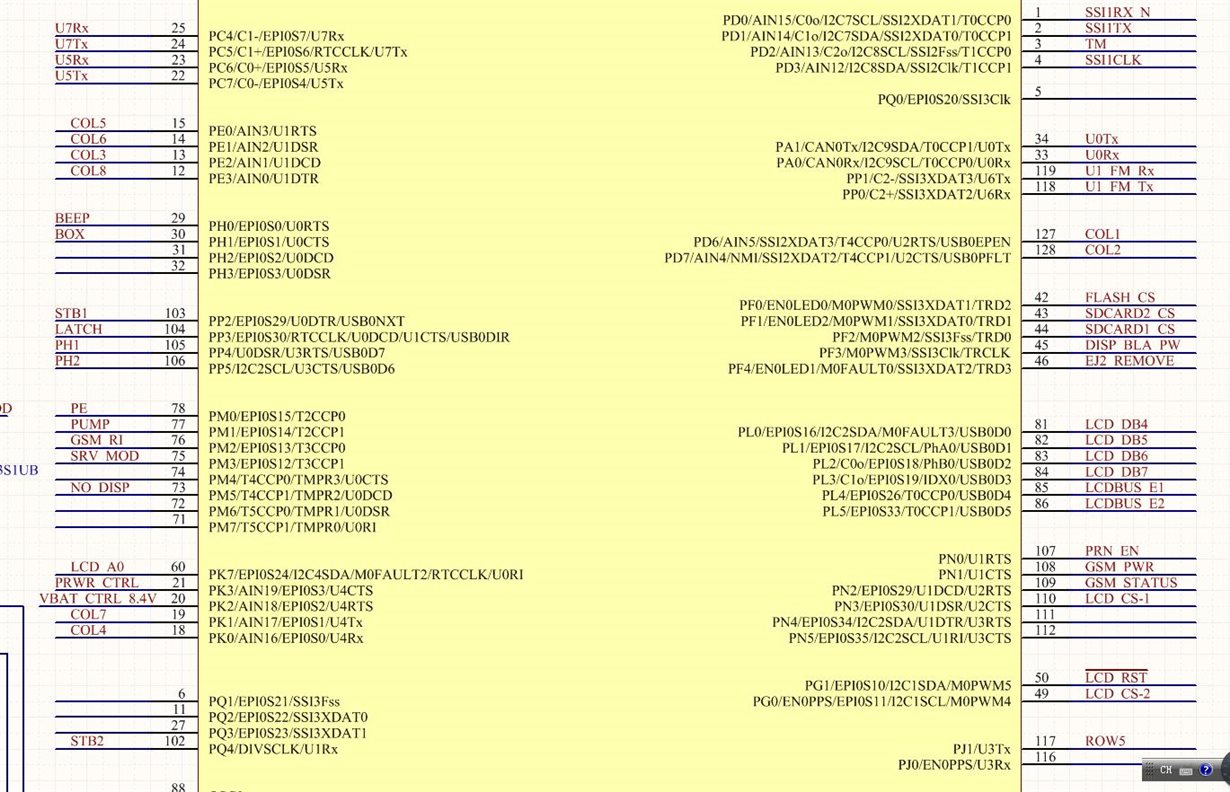

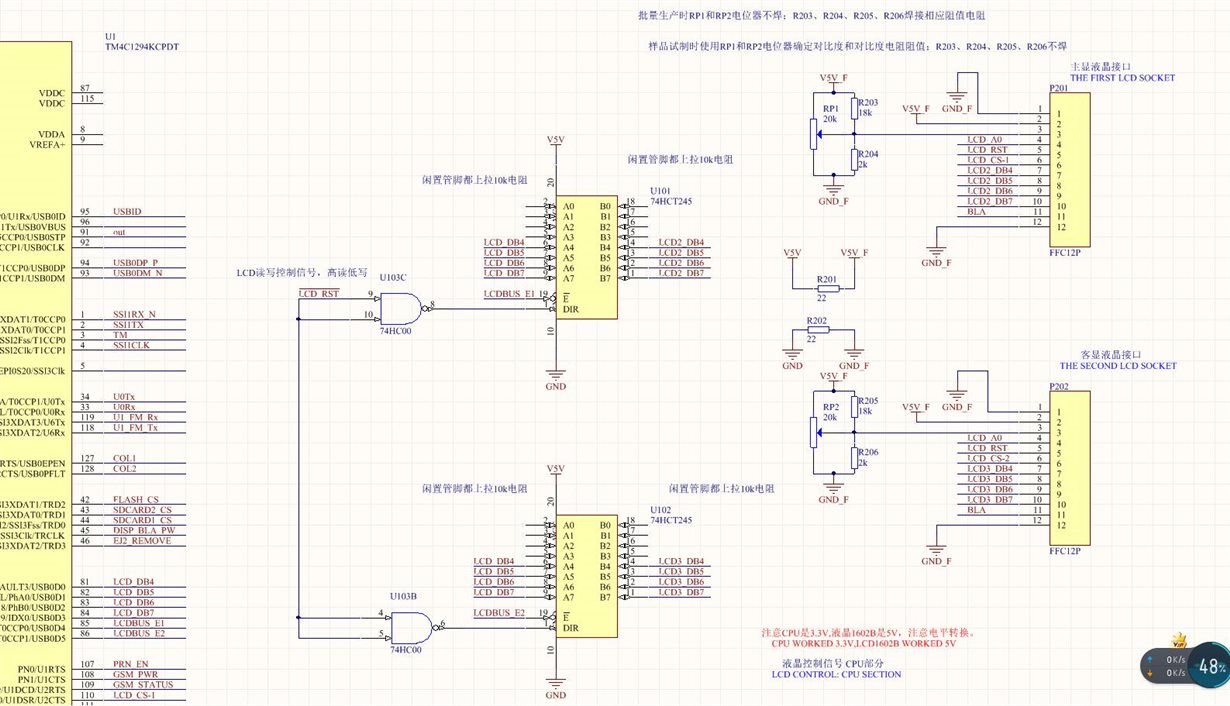

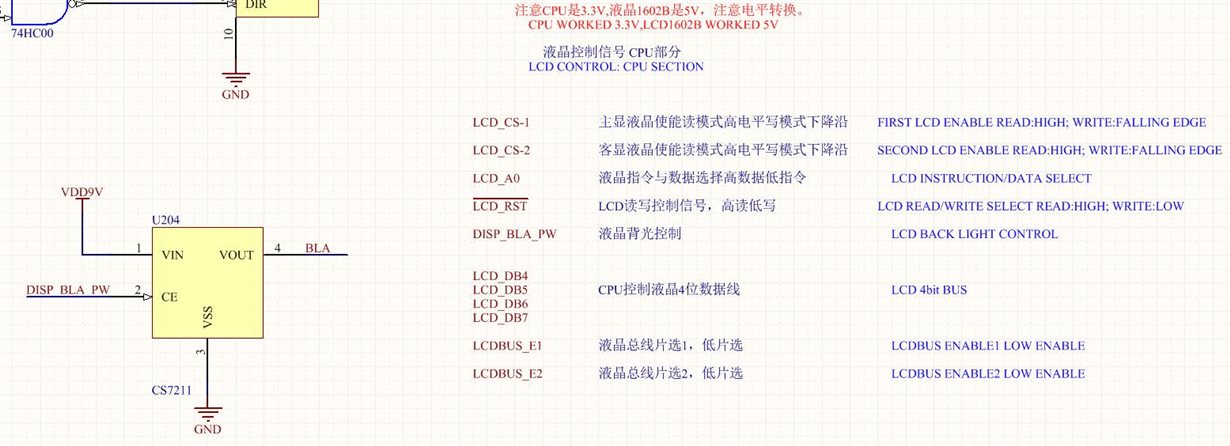

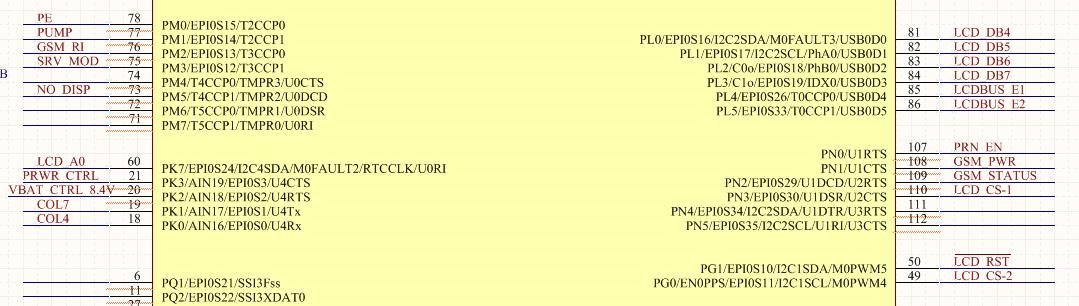

The first solution: the CPU is directly connected to the LCD. This solution is the simplest, but I don't know if the CPU can withstand the logic level of 5V, and whether the signal output by the CPU can pass the 30-50cm cable to the LCD. Does the CPU have this driving capability? ? Moreover, this scheme may not be very good when reading the liquid crystal (although it can be written and not read during programming).

Just change the LCD keyboard on the original product, the other parts are mature, I personally tend to connect directly but I am not sure about the processing of the interface, I hope you can give some advice.