Tool/software: Code Composer Studio

Hi,

I am new to TM4C123GH6PM.

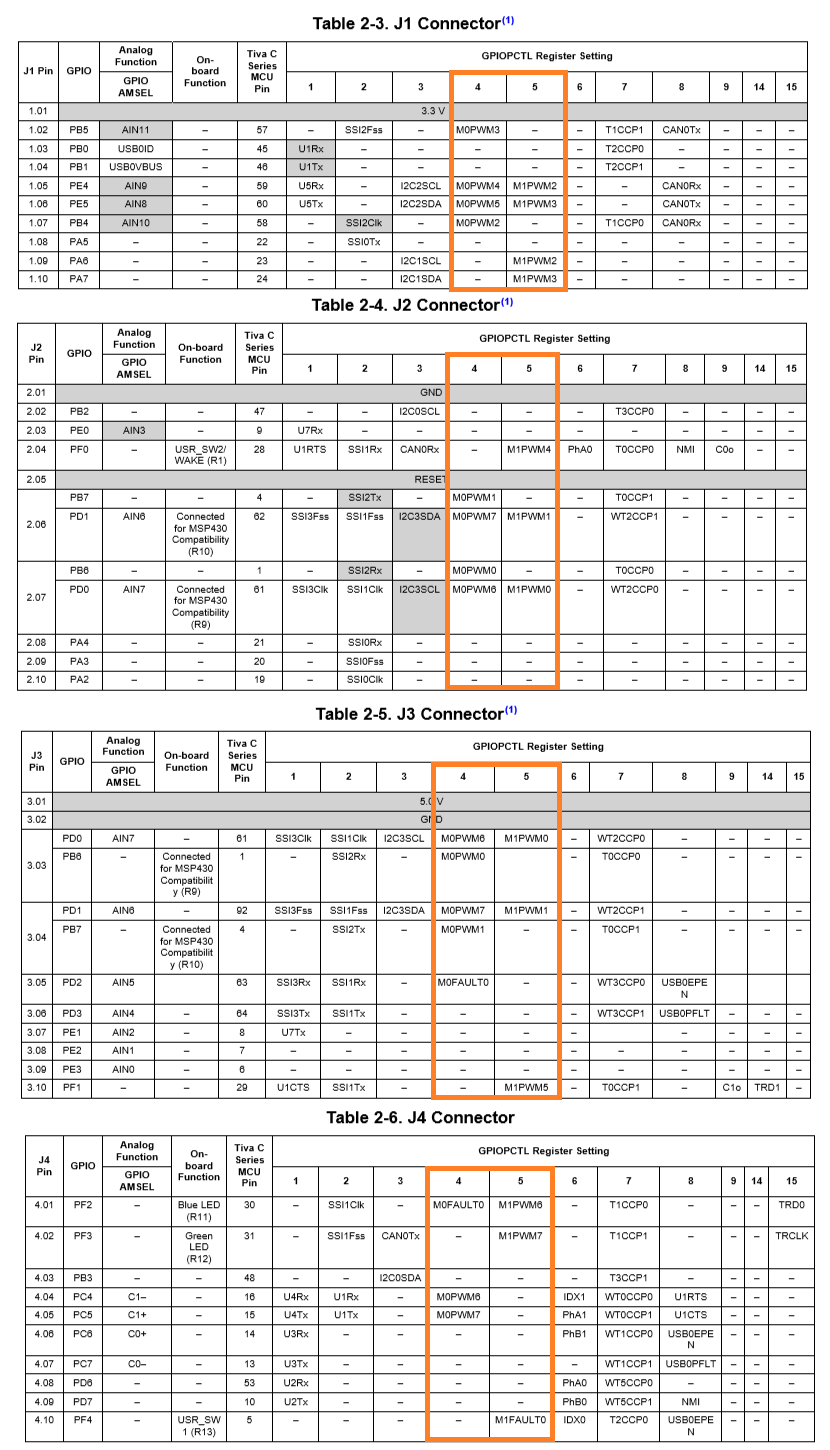

The pin out lists multiple functionality of TM4C board. Which 6 pwm pins I can configure as digital , to generate digital outputs.

PD0 and PB6 are connected together as AnalogIn , what does it means and can I use both pins to generate digital signals and how?

Please explain in brief about how to use different functionality of pins and what to avoid/

Thanks,

Ayushi