Other Parts Discussed in Thread: SN65HVD230

Tool/software: Code Composer Studio

Hello,

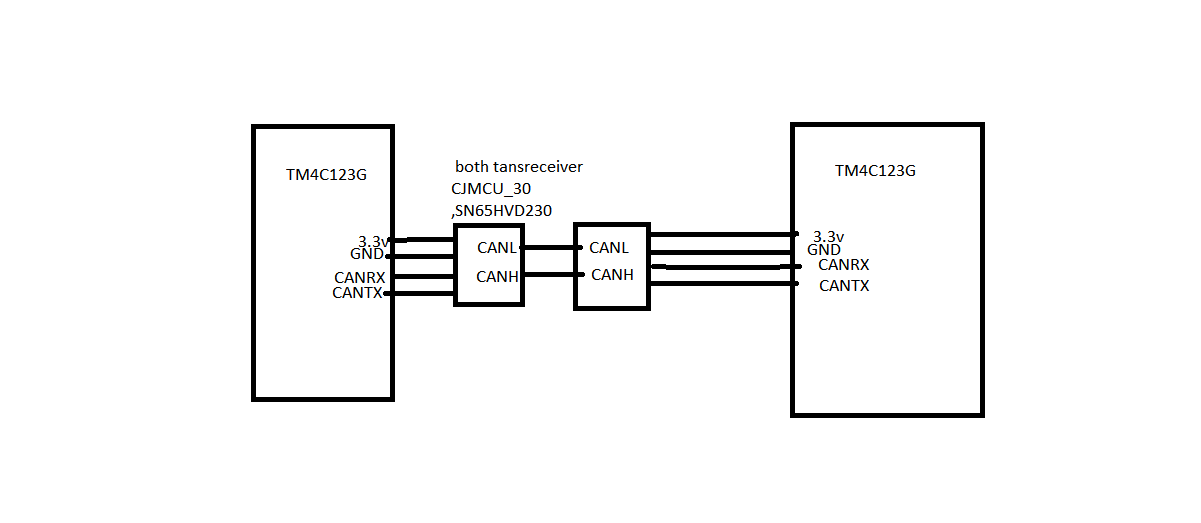

I am using 2 TM4C123GH6PM boards and CAN0 and UART0 of both the boards. I have taken CAN bus example from Dk-TM4C123G

board example. I have deleted the LCD part because I don't need this for my testing.

I am using 2 CJMCU-30 transceiver having IC SN65HVD230.

I am not getting output at all.

I have checked hardware connection, they are correct and the code is also error-free

and debugging properly.

I have changed CAN0 pins then also I am not getting

the output.

Please help me to find the solution to this problem