Other Parts Discussed in Thread: HALCOGEN,

Hi, I am right now taping the CAN communication between the sparkfun OBD-II UART board and OBD-II emulator by using the TMDX0MF066USB. I Had able to receive the data on CAN bus what is transmitting between two devices but I have unable to transmit the data. I Had set the both frematics and the TMS board to 250 kbps and 11 bit identifier.

as i observed that sparkfun is sending

(for example) 02 01 0D and emulator is responding with 03 41 32.

But same i am sending from the my TMS controller but I am not getting any response from emulator.

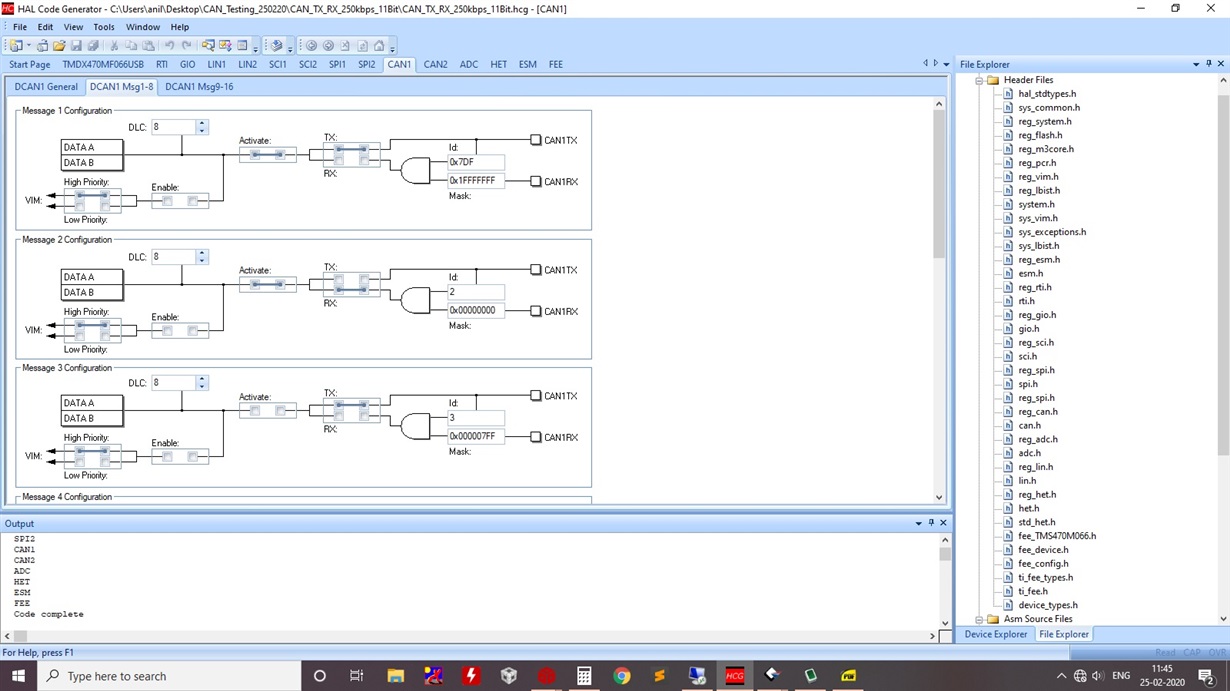

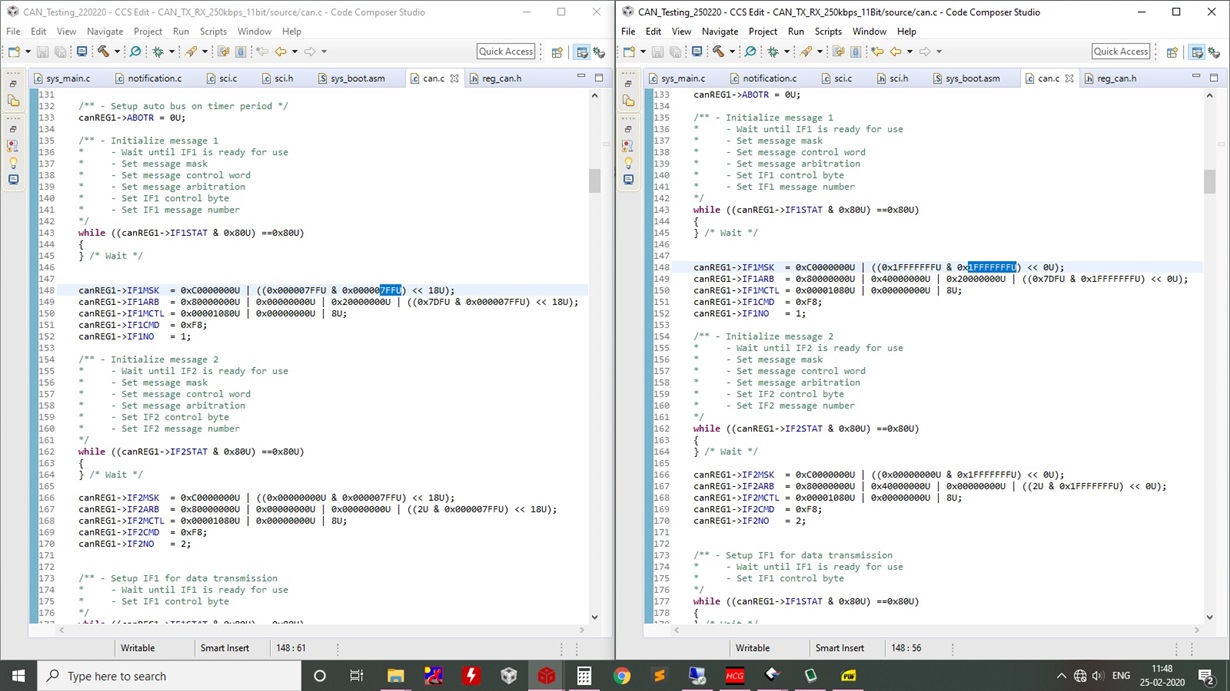

IS their any aditional changes required for TMS to send the data to OBD-II emulator like Message ID given as 7DF for emulator,if so how to set it? please Help me.

Regards,

Shiva