hi,

I bought a couple of this motor because it was cheap (5 eur) and includes the driver:

https://www.electronicoscaldas.com/datasheet/ULN2003A-PCB.pdf

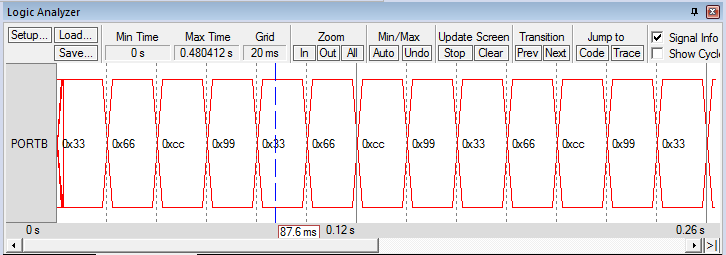

According to this data sheet the sequence of numbers is 0x3 0x6 0xC 0x9 .

I tried with the most simple program and connected just one motor to PB3-PB0:

while(1){

GPIO_PORTB_DATA_R =0x33;

SysTick_Wait10ms(2);

GPIO_PORTB_DATA_R =0x66;

SysTick_Wait10ms(2);

GPIO_PORTB_DATA_R =0xCC;

SysTick_Wait10ms(2);

GPIO_PORTB_DATA_R =0x99;

SysTick_Wait10ms(2);

}

It moves but I feel that something is wrong because current consumption is very very high (see the youtube video) and the motor gets a very high temperature

any idea about the problem?

it seems that TM4C123G output is correct (see keil uVision screen shot)

thanks in advance

Marcos