Tool/software: TI C/C++ Compiler

Hi! I'm sungmin

The thing that I want to do is

If my blood pressure signal goes into any Pin(for example, PE2), The output signal's form should be square waveform.

So, I tried PWM because the only thing that i remember was PWM.

BUT, PWM produces a square wave even if there is no input in the kit.

So, I tried to find another way.

that is

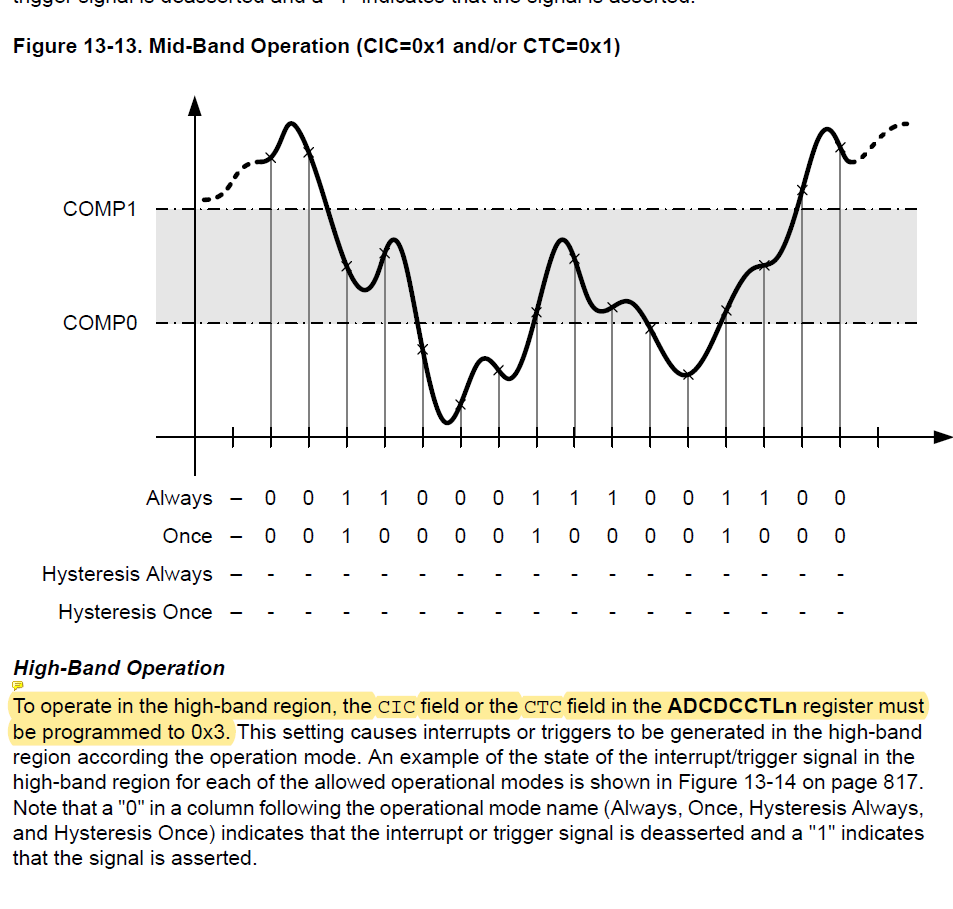

I thought thati could do it with 'Always-Mode' and 'high-band operation' with the same values of COMP1 and COMP0,

BUT, I am not sure if this is correct.

I have no one who can teach me.

please help me :( ....

I really want to put the pulse sensor output value in TM4C so that the output comes out as a sqaure wave.

and i know the thing

I am certain that the pulse sensor signal is sampled using ADC.