Other Parts Discussed in Thread: HALCOGEN

Hello,

In a project we would like to implement two current controls on the TMS570LS0914, which are to be controlled via a PWM signal.

- For the first PWM control the N2HET[30] (Pin 127) is used. An AD value is evaluated via AD1IN[21] (pin 65).

- For the second PWM control N2HET[14] (pin 125) is used. An AD value is evaluated via AD1IN[01] (pin 71).

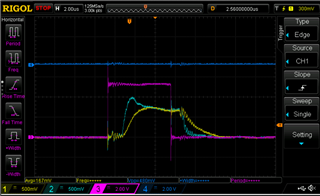

The duty cycle of a 16kHz PWM signal is to be controlled. An AD value is to be measured and evaluated at a high level. The problem at this point is that the duty cycle can reach <10%, whereby the duration of a high level is < 7us. The following photo shows the signal (relevant signals: purple = PWM signal, yellow = signal at the AD pin):

Here I have the following questions:

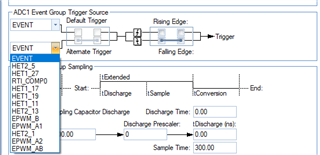

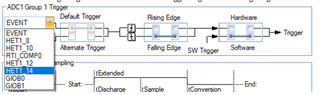

- What is the ideal way to allow timing of AD conversion at such short levels?

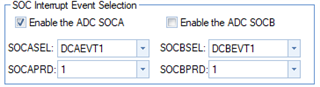

- For the second control, EVENT based triggering of the conversion is possible. Could this already be the solution to our problem?

- Is a precise AD conversion possible with the first control variant and the current hardware wiring (N2HET[30] (pin 127) & AD1IN[21] (pin 65))? Unfortunately EVENT based triggering would not be possible with this variant.

Thank you in advance for your help.