Other Parts Discussed in Thread: C2000WARE, REF6025, OPA350, THS4031, OPA320, OPA2320

Hi Expert

Customer report the F28388 16bit ADC result is not accuracy and linearly enough. I try validate it as below:

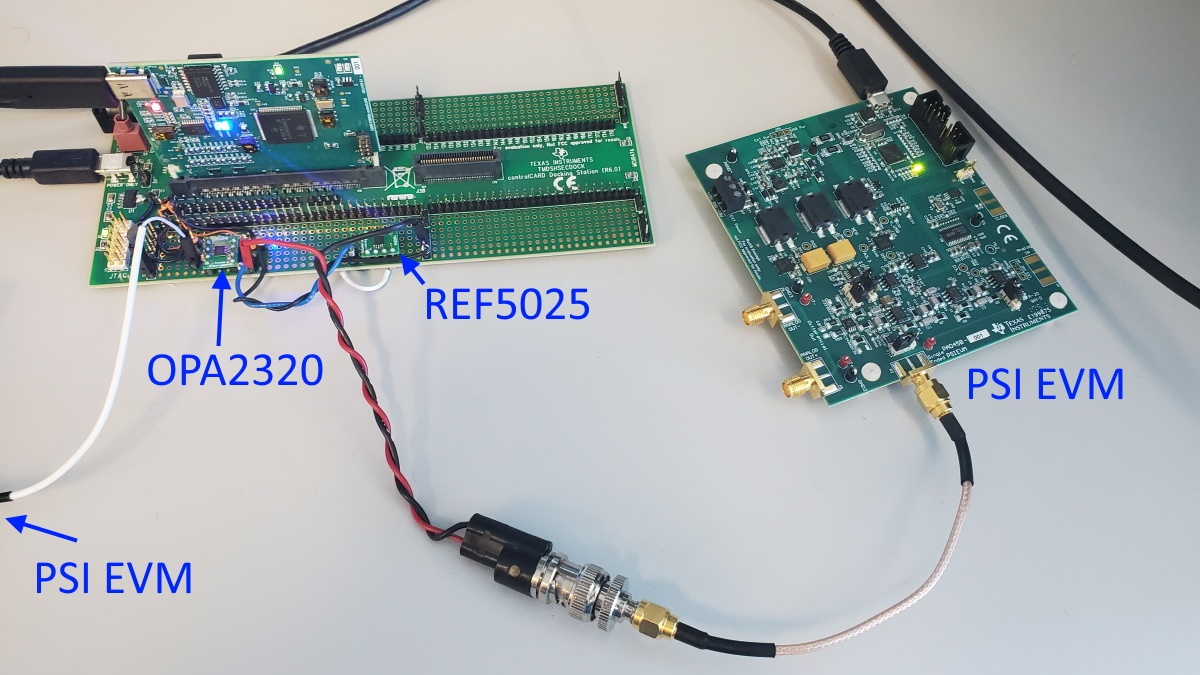

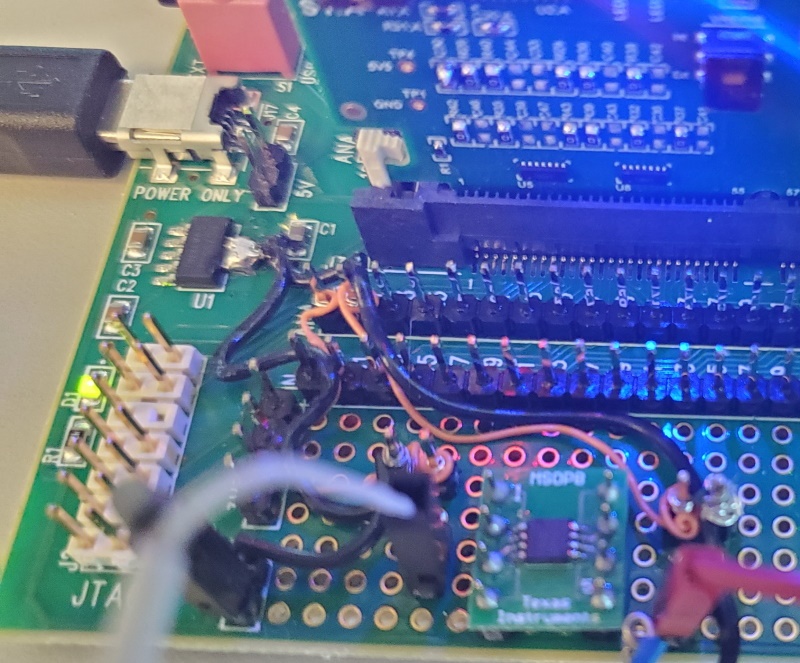

Hardware: F28388 control card + Experimenter Kits; connect a 2.5V Battery +/- as signal source to ADCA pin A0 & pin GND in Experiment Kit

Firmware : adc_ex2_soc_epwm from "C2000Ware_3_03_00_00\driverlib\f2838x\examples\c28x\adc"; with ADC_setMode(ADCA_BASE, ADC_RESOLUTION_16BIT, ADC_MODE_SINGLE_ENDED);

Result: real-time check the adcAResults[256] in CCS, and found the difference could up to 500 LSB between max and min value. I think it is much worse than ADC spec in datasheet.

May I get advice how we should setup the hardware and firmware to get stable and accuracy 16bit ADC result?