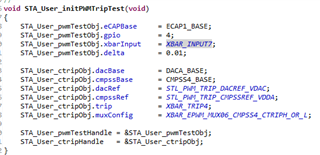

Hi, i'm trying to port the PWM duty cycle self test from 379D to the 388D but the test is run on the CPU2, my problem is that in the self test code there is an instruction to set the inputselect register (

EALLOW;

HWREGH(base + XBAR_O_INPUT1SELECT + (uint16_t)input) = pin;

EDIS;

) but when i debug it seems that it is not set, in addition to the fact that i can not visualise the register from CPU2 and i have to stop running the CPU1 to be able to see it's content.