Tool/software:

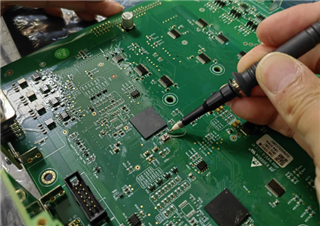

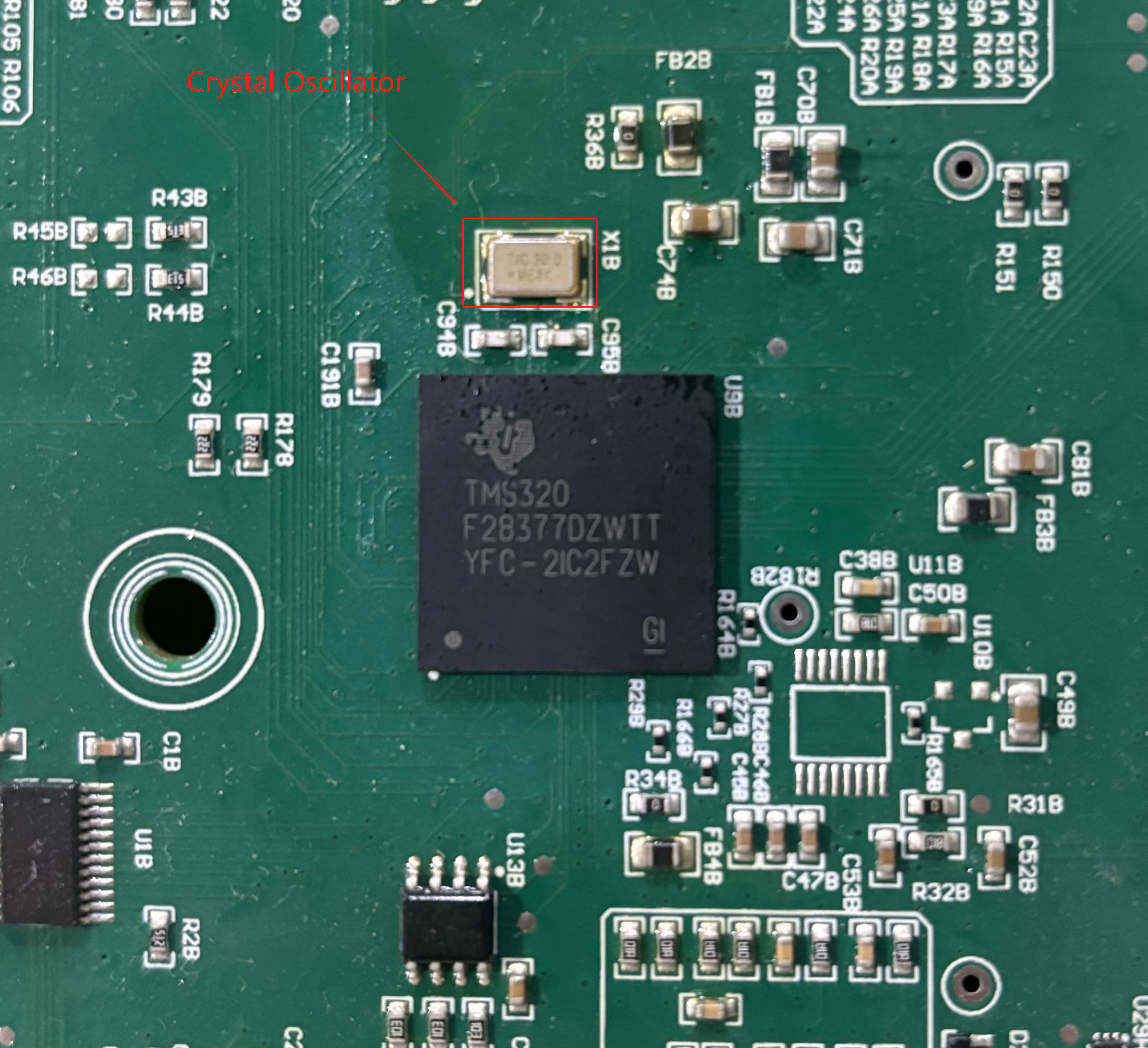

Hello, I have a question regarding my DSP28377D board. It has been running normally for some time, but occasionally (it has happened many times, with a probability of about 1%) the program fails to run. Based on experience, I first checked the crystal oscillator (a passive crystal oscillator), and found that it was not oscillating. During troubleshooting on multiple problematic boards, we encountered the following phenomena:

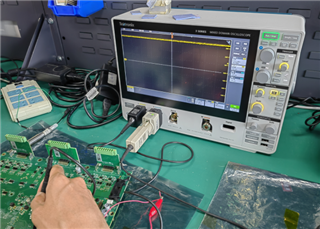

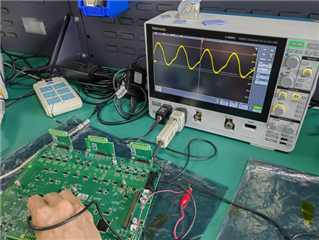

1. When attempting to use an oscilloscope to observe whether the crystal oscillator was working, just by touching the load capacitor with the oscilloscope probe, the board started functioning correctly, and the program ran as expected. This happened with some of the boards.

2. On problematic boards, using hot air or an oven to heat them also resulted in the boards functioning correctly, and the program ran as expected. This occurred with some of the boards.

3. For most boards, the above methods did not resolve the issue.

4. By replacing the crystal oscillator with a new one, we still found that the new crystal did not oscillate.

5. By replacing the DSP28377D chip, the board functioned normally.

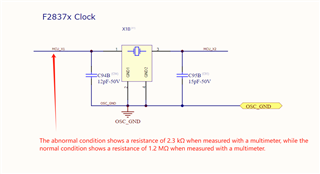

6. The resistance across the load capacitors on normally functioning boards is 1.2 MΩ, while the resistance across the load capacitors on malfunctioning boards is 2.3 kΩ.

Could you please advise me on how to troubleshoot this issue? This problem has occurred many times now. Thank you!

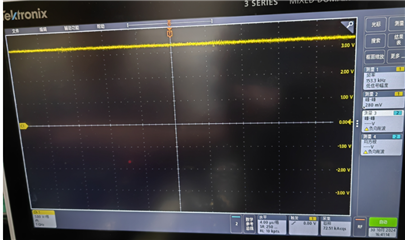

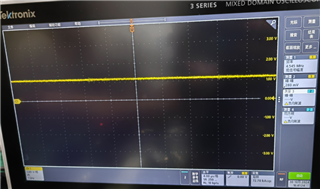

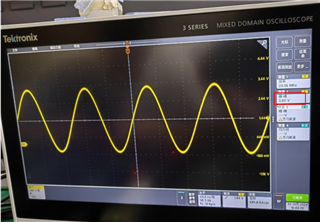

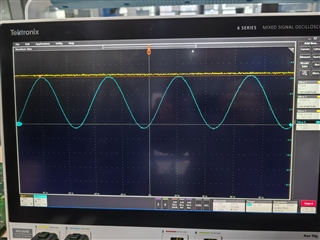

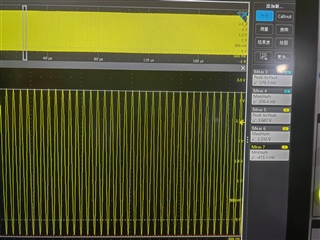

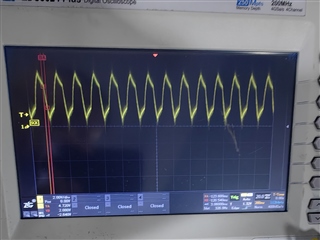

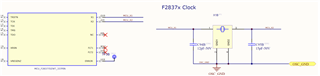

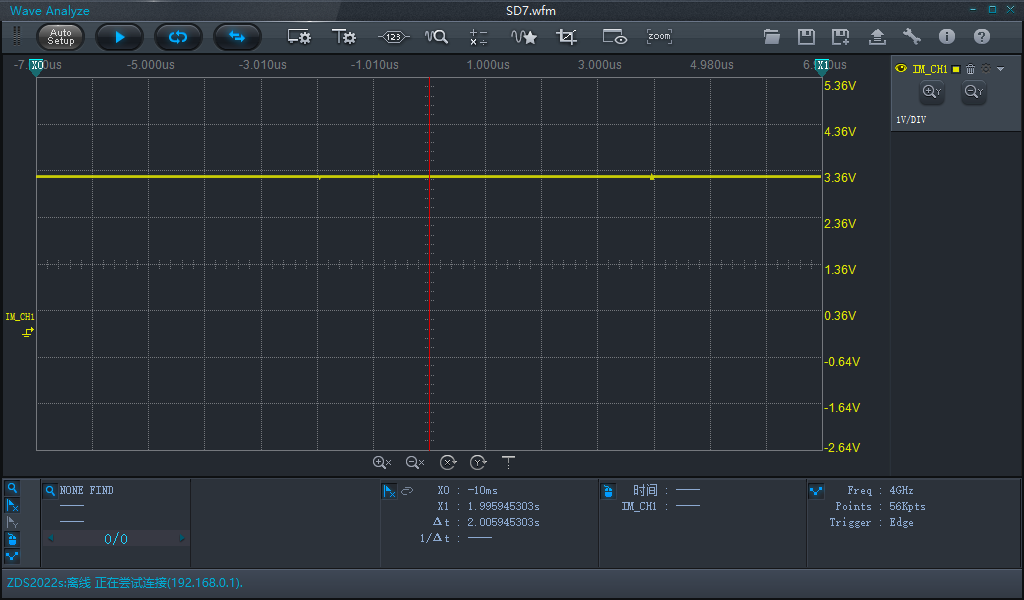

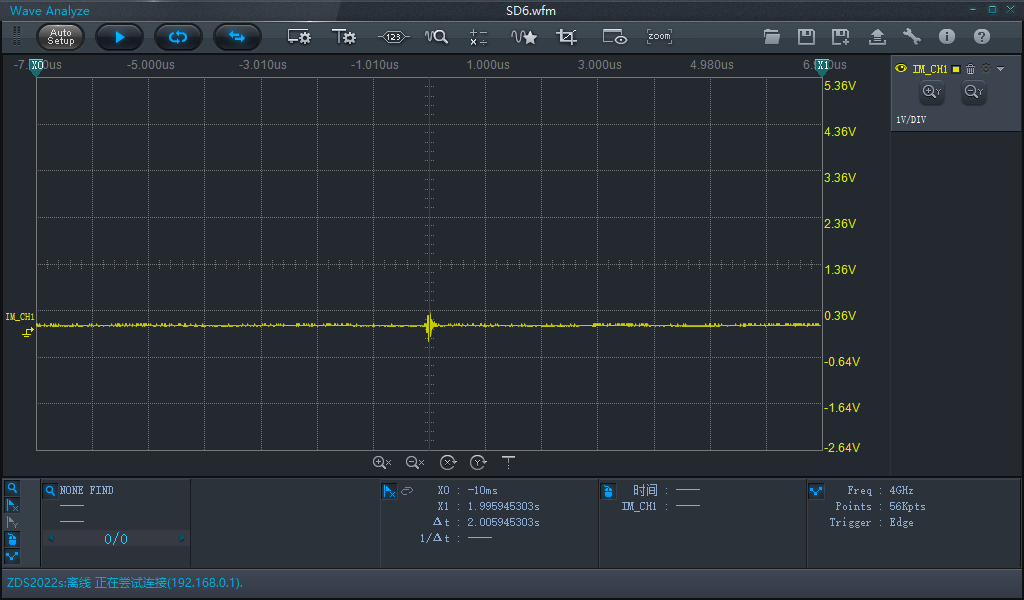

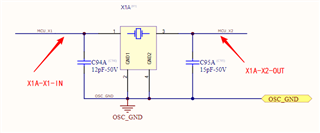

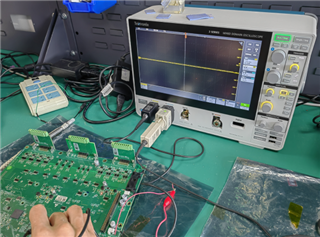

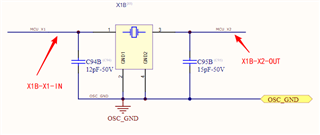

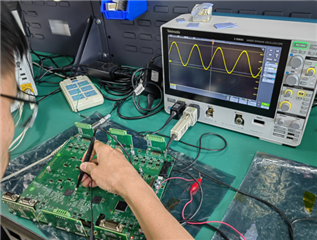

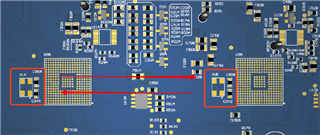

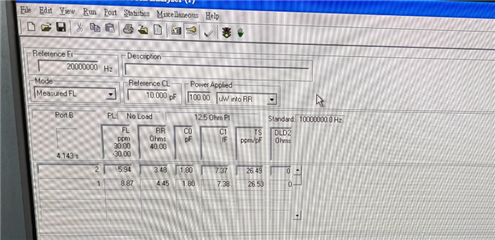

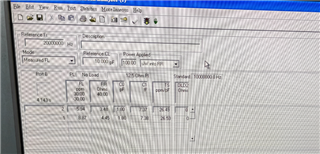

The circuit diagram connecting the crystal oscillator to the DSP is shown below, and the waveform of the malfunctioning crystal oscillator is also shown below:

5、

5、