- Ask a related questionWhat is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

Tool/software:

Use the TM3200F28069M KIT board with the DRV8353RH KIT to conduct the motor operation test.

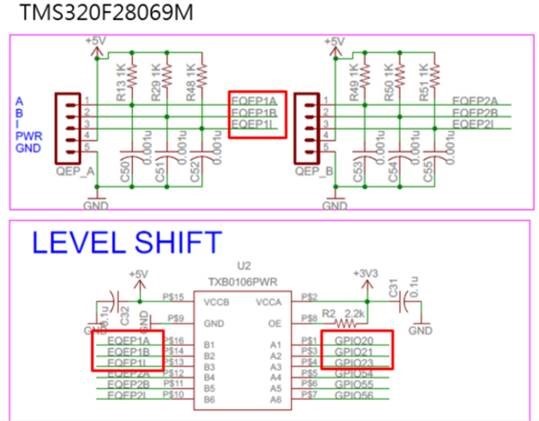

We first used Lab1b to enable open loop operation. The motor is equipped with a position sensor with a resolution of 1024PPR and a QA.QB.Index signal output.

We query the corresponding TI Lab sample program for Lab 12a.

, the include HAL files are hal.c and drv8353.c of drv8353.

We have also confirmed that PWM, GPIO, ADC, and QEP announced GPIO Number pins.

The motor parameters have been adjusted using the parameters FAE and R&D tried.

Change the value according to the specifications of each PDF file. The program receives the Encoder signal and calculates the rotor position.

Running the Lab 12a program can start, but the motor stops soon, and the error message is gMotorVars.SpinTAC.VelIdErrorID 2003,

so if you have any questions, please ask:

1. The motor uses a position sensor Encoder. Is the corresponding sample program Lab 12a? Which one can be driven normally?

2. Does the Lab 12a sample program use the startup position sensor? How do we adjust so that we can all use position sensors to operate instead of Sensorless operation?

Please help with the above issues, thank you.

Hello,

Are you using MotorWare in this case? If so, are you using InstaSPIN-FOC or InstaSPIN-MOTION? What is the directory of the project you're using?

Regards,

Jason Osborn

Hi Jason

The information used and referenced is as follows:

1. Lab 1b

A. Project path C:\ti\motorware\motorware_1_01_00_18\sw\solutions\insstapin_foc\boards\boostxldrv8301_revB\f28x\f2806xF\projects\ccs

B. Using Instaspin_foc

C. The Gate driver uses DRV8353RH. Use the recommended method below to modify the DRV8353RH settings and modify the hal_obj.h hardware configuration, so the motor can use Lab 1b for open-loop operation.

"LAUNCHXL-F28069M: Configuration with DRV8353RS-EVM problems - C2000 microcontrollers forum - C2000︎ microcontrollers - TI E2E support forums"

2. Lab 12a

A. Project path C:\ti\motorware\motorware_1_01_00_18\sw\solutions\insstapin_motion\boards\boostxldrv8301_revB\f28x\f2806xM\projects\ccs

B. Using Instaspin_motion

The Gate driver uses DRV8353RH. Please use the suggested methods below to modify the DRV8353RH settings and modify the hal_obj.h hardware configuration.

LAUNCHXL-F28069M: Configuration with DRV8353RS-EVM problems - C2000 microcontrollers forum - C2000︎ microcontrollers - TI E2E support forums

C. hal.c, hal.h and hal_obj.h refer to the settings of Lab 13a. The subroutine of ENC and the subroutine of QEP will need to be modified. Only then can you confirm that the program has received the change value of QEP and ENC has angle conversion. , the motor will start.

thanks.

Hello,

Apologies for the delay.

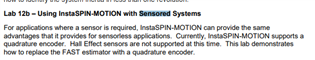

InstaSPIN-FOC is a sensorless algorithm. Referring to the InstaSPIN lab guide, located at {motorware_installation}/docs/labs/instaspin_labs.pdf:

The guide provides instructions on the use of InstaSPIN-MOTION with hardware sensors. Although many of the principles will be the same to utilize InstaSPIN-FOC, I would recommend following the intended lab's guidance for initial verification and to become familiar with the codebase prior to adjusting the implementation.

Regards,

Jason Osborn

Hi Jason

Thanks for your reply. We have already followed the lab setup for the Lab 12a’s codebase. How can we adjust it so that we can use position sensors to operate instead of operating sensorlessly?

The lab user's guide document prev. mentioned has the test procedure for lab 12a, which describes replacing a sensorless estimator with a sensor output.

Regards,

Jason Osborn

Hi Jason,

I have completed the changes according to the steps in Lab 12a, but I still have some issues:

1.The motor is unable to rotate and is triggering Error ID 2004, even though the target speed has been reduced to 10 RPM.

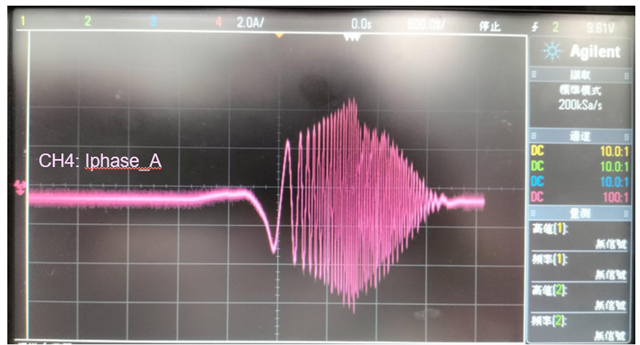

2. We are driving the motor with a fixed speed of 750 RPM to send a signal to the encoder. However, I noticed that the speed fluctuates between 600 and 1000 RPM.

Per the InstaSPIN user's guide page 185, ERR_ID = 2004 indicates that the torque profile process timed out, and ERR_ID = 2003 indicates a negative inertia was calculated.

High speed fluctuation with incorrect inertia estimation makes sense.

To confirm, the entire process in the instaspin_labs.pdf document from pages 273 to 281 was followed?

Regards,

Jason Osborn