Part Number: C2000WARE-MOTORCONTROL-SDK

Other Parts Discussed in Thread: MOTORWARE, BOOSTXL-DRV8320RS, DRV8320, LAUNCHXL-F280049C, DRV8323

Tool/software:

Hello,

We would like to follow up on this question, because as it seems, we are facing exactly the same issue as reported in this thread and no adequate answer can be found on the whole forum.

Recently we made a transition from F28069M (using MotorWare) to 3rd generation processor F280041C (using MCSDK 5.0.0.3) on our motor controller board, designed for high-power application with a low-inductance motor. On the previous version, which uses MotorWare, we’ve successfully run the motor up to 3kW without any issues. Now we are struggling to get higher with RPMs than some point around 9000. To avoid the effect of the speed controller, we also tried torque control mode with the Iq setpoint. We also verified that the output parameters of the identification process are almost identical as with the old version.

Parameters of the system:

PWM freq. : 20kHz

ISR freq: 20kHz

Current control freq. : 20kHz

Speed control freq. : 2kHz

Voltage filter pole freq.: 654Hz

Voltage ADC scale: 39.685

Current ADC scale: 825

Max VS mag: 0.5

Identified parameters of the motor:

USER_MOTOR_Rs_Ohm 0.0110599976

USER_MOTOR_Ls_d_H 3.74998126e-06

USER_MOTOR_Ls_q_H 3.74998126e-06

USER_MOTOR_RATED_FLUX_VpHz 0.00662664603

USER_POLE_PAIRS 7

Our observations:

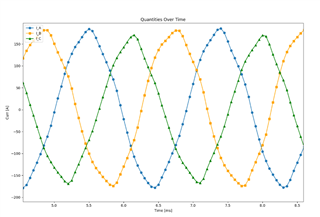

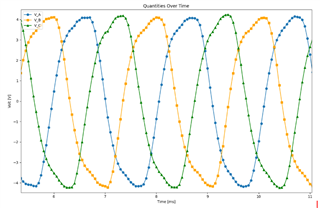

1. Using torque control mode with Iq setpoint higher than 170A, the estimated RPM differs from real measured RPM with external optical sensor. Setting the setpoint higher does not further increase the RPM.

2.Currents and voltages sampled on all three phases look good around the 170A Iq setpoint. But if the setpoint is set higher reaching some point things go crazy and distortion is visible on current and also on angle estimation. The same happens when we try to push RPM higher in speed control mode.

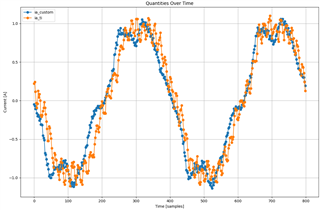

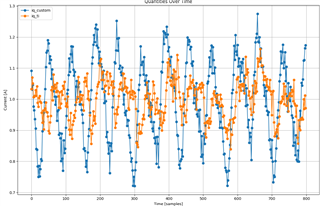

3.Iq current seems to oscillate more than expected (captured in torque control mode with Iq step from 5 to 10A).

We of course also tried to tune PI parameters of the current regulators, but it had no significant effect on oscillations.

4.There are 3 new parameters in the code, which have significant impact on the system, but there is no adequate definition of them. We would appreciate some information on what these parameters really do in the estimator and how to tune them.

USER_EST_FLUX_HF_SF - increasing this value higher than default 0.125 value, sets the maximum achievable RPM lower. Setting it to value 1, we were not able to reach more than ~7000 RPM.

USER_EST_FREQ_HF_SF - seems to have no effect

USER_EST_BEMF_HF_SF - has significant impact on RPM estimation.

It seems that from some reason the MotorControl SDK acts differently from MotorWare in the high power/RPM range and we need to understand why. We decided to move to this new generation of processors with the view of achieving higher performance, unlocking new possibilities and avoiding the obsolescence of older components. However, this has so far led to these issues and delays in delivering our devices to customers on time. We would really appreciate your help.